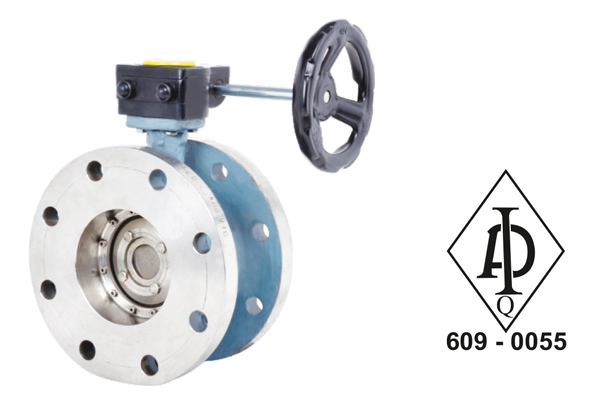

“4Matic” offers Manual Worm Gear / Lever Operated Off – Set Disc Butterfly Valve Double Flange

Construction engineered for multiply ON/OFF Operation in the large Pipe line and full flow down Stream

Size Range : 3″ to 24″

| Standard | |

| Design And Manufacturing | API 609 / BS 5155 / BSEN 593 / IS 13095 |

| Valve Face To Face Dimension | API 609 ( Short Pattern ) / BS 5155 ( Long Patern ) IS 13095 ( Long Patern ) |

| Flange Standard Conformity | ASME / ANSI B 16.5 Class 600 |

| Inspection & Testing | API 598 |

| PRESSURE / TEMPERATURE RATING | |

| PRESSURE RATING | 600# ( PN 60 ) |

| OPERATING TEMPERATURE | NBR – -10 °C TO +90 °C / EPDM – -20 °C TO +120 °C |

| VITON – 0 °C TO +220 °C / PTFE – -25°C TO +180 °C | |

| RPTFE – -25 °C TO +250°C | |

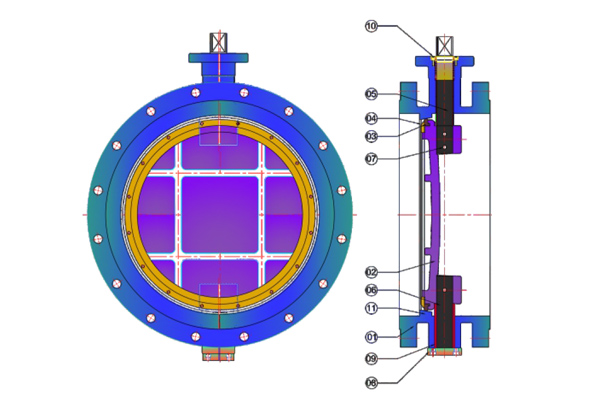

| No. | Description | Material | Qty. |

| 1 | Body | ASTM A 216 Gr. WCB / A 351 Gr. CF8 / CF8M | 01 |

| 2 | Disc | ASTM A 216 Gr. WCB / A 351 Gr. CF8 / CF8M | 01 |

| 3 | Disc Seal Ring | PTFE / RPTFE / NBR / EPDM / Viton | 01 |

| 4 | Retainaer | IS 2062 Gr B M.S. / ASTM A 351 Gr. CF8 / CF8M | 01 |

| 5 | Shaft | ASTM A 479 Type 410 / 304 / 316 | 01 |

| 6 | Stem Shaft | ASTM A 479 Type 410 / 304 / 316 | 01 |

| 7 | Disc Pin | S.S. 304 | 02 |

| 8 | Steam Plate | M.S. | 01 |

| 9 | Shaft Bush | ASTM A – 479 Type 410 / 304 / 316 | 02 |

| 10 | Gland Plate | M.S. | 01 |

| 11 | Body Seat Ring | ASTM A 479 Type 304 / 316 | 01 |

| Butterfly Valve CV Values | ||||||||||

| Valve Size | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| MM | Inch | |||||||||

| 80 | 3″ | 4 | 15.6 | 31.5 | 47.6 | 74.5 | 110 | 180 | 200 | 230 |

| 100 | 4″ | 8 | 27.9 | 56 | 90 | 130 | 190 | 310 | 350 | 400 |

| 125 | 5″ | 13.1 | 46 | 92 | 150 | 220 | 310 | 520 | 580 | 670 |

| 150 | 6″ | 19.9 | 70 | 140 | 220 | 330 | 480 | 780 | 890 | 1000 |

| 200 | 8″ | 36.3 | 130 | 260 | 400 | 610 | 860 | 1430 | 1600 | 1830 |

| 250 | 10″ | 56 | 200 | 390 | 620 | 920 | 1300 | 2170 | 2450 | 2780 |

| 300 | 12″ | 84 | 290 | 590 | 930 | 1400 | 1980 | 3290 | 3700 | 4200 |

| 350 | 14″ | 100 | 370 | 730 | 1140 | 1700 | 2500 | 4060 | 4570 | 5200 |

| 400 | 16″ | 140 | 480 | 960 | 1500 | 2300 | 3220 | 5340 | 6020 | 6840 |

| 450 | 18″ | 1180 | 640 | 1260 | 2000 | 3000 | 4220 | 7000 | 7900 | 9000 |

| 500 | 20″ | 240 | 840 | 1680 | 2600 | 3950 | 5630 | 9300 | 10500 | 12000 |

| 600 | 24″ | 380 | 1300 | 2630 | 4200 | 6200 | 8800 | 14600 | 16500 | 18700 |

| VALVE TORQUE 600# | ||||||

| Valve Size | 30 Bar N – m |

40 Bar N – m |

60 Bar N – m |

80 Bar N – m |

100 Bar N – m |

|

| MM | Inch | |||||

| 150 | 6″ | 600 | 700 | 850 | 1000 | 1300 |

| 200 | 8″ | 1000 | 1150 | 1400 | 1650 | 2100 |

| 250 | 10″ | 1650 | 1900 | 2300 | 2800 | 3800 |

| 300 | 12″ | 2400 | 2850 | 3450 | 4100 | 4900 |

| 350 | 14″ | 3400 | 4300 | 5350 | 6300 | 7500 |

| 400 | 16″ | 5000 | 6900 | 8900 | 9700 | 11500 |

| 450 | 18″ | 7000 | 9400 | 12000 | 14500 | 17000 |

| 500 | 20″ | 8700 | 12000 | 15000 | 18000 | 21000 |

| 600 | 24″ | 15000 | 21000 | 25700 | 30500 | 36000 |

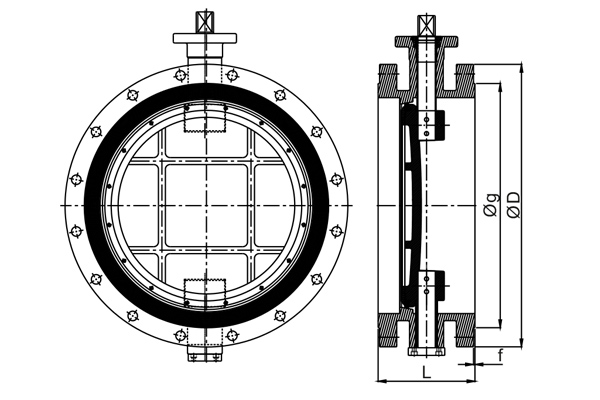

| Dimensions : 600# (All Dimensions are in mm) | ||||||||||

| Valve Model | Valve Size | L | ØD | Øg | b | f | ØJ | N | K:PCD | |

| MM | Inch | |||||||||

| BOD3C-80 | 80 | 3″ | 180 | 210 | 127 | 31.75 | 6.35 | 22.0 | 08 | 168.3 |

| BOD3C-100 | 100 | 4″ | 190 | 275 | 157 | 38.1 | 6.35 | 25.4 | 08 | 215.9 |

| BOD3C-125 | 125 | 5″ | 210 | 330 | 185 | 44.4 | 6.35 | 28.5 | 08 | 266.7 |

| BOD3C-150 | 150 | 6″ | 210 | 355 | 216 | 47.75 | 6.35 | 28.5 | 12 | 292.1 |

| BOD3C-200 | 200 | 8″ | 230 | 420 | 270 | 55.63 | 6.35 | 32.0 | 12 | 349.2 |

| BOD3C-250 | 250 | 10″ | 250 | 510 | 324 | 63.5 | 6.35 | 35.0 | 16 | 431.8 |

| BOD3C-300 | 300 | 12″ | 270 | 560 | 381 | 66.55 | 6.35 | 35.0 | 20 | 489.5 |

| BOD3C-350 | 350 | 14″ | 290 | 605 | 413 | 69.85 | 6.35 | 38.1 | 20 | 527.0 |

| BOD3C-400 | 400 | 16″ | 310 | 685 | 470 | 76.2 | 6.35 | 41.15 | 20 | 603.2 |

| BOD3C-450 | 450 | 18″ | 330 | 745 | 534 | 82.6 | 6.35 | 44.45 | 20 | 654.0 |

| BOD3C-500 | 500 | 20″ | 350 | 815 | 584 | 88.9 | 6.35 | 44.45 | 24 | 723.9 |

| BOD3C-600 | 600 | 24″ | 390 | 940 | 692 | 101.6 | 6.35 | 50 | 24 | 838.2 |