PTFE Lined Butterfly Valves

4Matic PTFE lined valves are well suited for consistent performance requirements in highly corrosive applications involving chlorine, benzene, sulphuric acid, nitric acid, phosphoric acid, hydrochloric acid and sea water. Virgin grade resins and thick fluoropolymer linings provide for superior resistance to corrosive chemical effects, absorption and swelling.

Size Range : 2″ to 12″

- Design and Manufacturing : API 609 Category A / BS 5155 / MSS SP-67 / AWWA C504

- Valve Face to Face Dimensions:Short Wafer as per ISO 5752 Tab 5 / API 609 Category A

- Top Flange Drilling : ISO 5211 Part II

- Inspection and Testing : API 598 / BS 6755 / FCI-70-2

- Flanged Standard Conformity : ANSI 150, DIN PN 10 / 16

Advantages

- Precision Spherically Molded & Machined One Piece Disc/Stem.

- Minimum 3mm Thick FEP/PFA Liner.

- Integral Actuator Mounting Flange.

- ISO 5211 Mounting Flange.

- Dynamically Loaded Mechanical Shaft Seal.

- Radially Loaded Atmospheric Seal.

- Enhanced Resilient 360 degrees Elastomeric Energizer.

- High Strength Fasteners.

- Blowout Proof Stem.

- Chambered PFA Raised Face Flange Sealing.

- Epoxy Coated Body.

PTFE (FEP – PFA) Lined Butterfly Valve with Pneumatic Actuator

- Size :2″ to 20″

- MOC : WCB / CF8 / CF8M / CF3M

- Seals: FEP / PFA

- Pressure : 10 Kg/cm2

- Temperature : FEP 180°c / PFA 230°c

- Ends : Wafer Type

FEP / PFA Lined & Muffler Butterfly Valve

“4Matic” Offers FEP / PFA Lined Butterfly Valve for Corrosive Application. The FEP / PFA Seat Lined Covers the entire Wetted Surface of the body and Extends on to the Flanged Contact face – thus eliminating possibility of any media contact with the body.

Size Range : 2″ to 12″

| Standard | |

| Design And Manufacturing | API 609 category A/BS 5155 / MSS SP-67 / C-504 |

| Valve Face To Face Dimension | Short wafer as per ISO 5752 Tab 5 / API 609 Category A |

| Flange Standard Conformity | ISO 5211 Part II |

| Inspection & Testing | API 598 / BS 6755 / FCI-702 |

| Top Flange Driling | ANSI 150, DIN PN 10 / 16 |

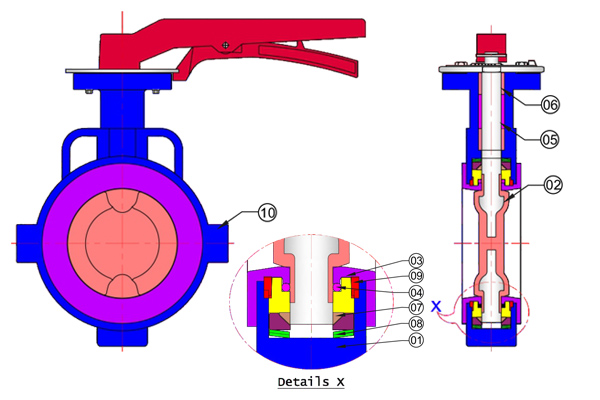

| No. | Description | Material | Qty. |

| 1 | Body | C.I. / C.S. / CF8 / CF8M | 01 |

| 2 | Disc | C.I. / C.S. / CF8 / CF8M | 01 |

| 3 | Sleeve | FEP / PFA | 01 |

| 4 | ‘O’ Ring | Viton | 02 |

| 5 | Bush | PTFE | 02 |

| 6 | Bush | Metal Bush S.S. 304 | 02 |

| 7 | Truth Bush | S.S. 304 | 02 |

| 8 | Washer | Spring Steel | 04 |

| 9 | Gasket | Silicon Big | 02 |

| 10 | L. N. Bolt | S.S. 304 | 02 |

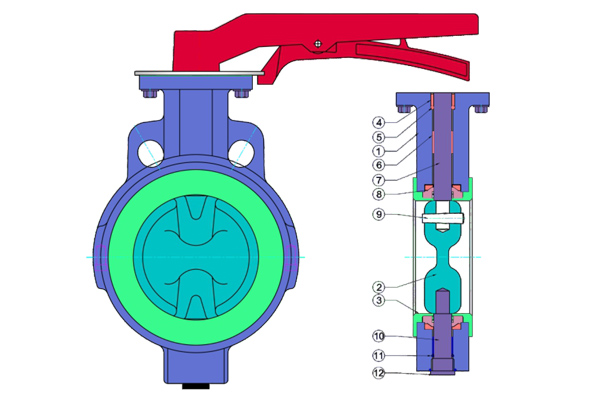

| No. | Description | Material |

| 1 | Body | C.I. / D.I. / CF8 / CF8M |

| 2 | Disc | C.I. / I.I. / CF8 / CF8M |

| 3 | Seat | PTFE |

| 4 | Collar | PTFE |

| 5 | “O” Ring | Viton |

| 6 | Metal Bush | PTFE Coated |

| 7 | Top Shaft | AISI 410 |

| 8 | Pad | Silicon |

| 9 | Disc Pin | S. S. 304 |

| 10 | Bottom Shaft | AISI 410 |

| 11 | “O” Ring | Viton |

| 12 | Plug | M. S. |

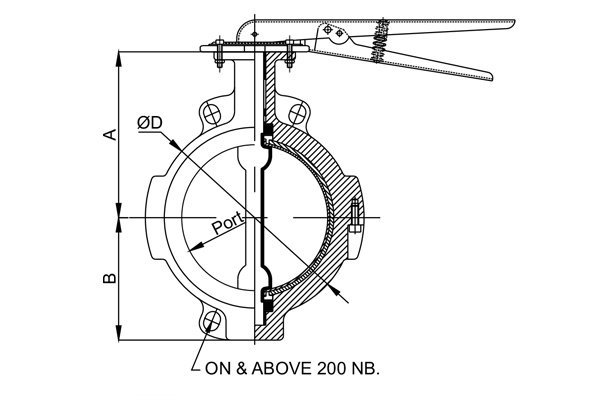

| Dimensions : (All Dimensions are in mm) | |||||||

| Valve Model | Valve Size | Port | A | B | F to F | ØD | |

| MM | Inch | ||||||

| 4M-BF-LV-50 | 50 | 2″ | 48 | 107 | 65 | 44 | 101 |

| 4M-BF-LV-65 | 65 | 2.1/2″ | 62 | 118 | 65 | 46 | 112 |

| 4M-BF-LV-80 | 80 | 3″ | 78 | 122 | 83 | 46 | 130 |

| 4M-BF-LV-100 | 100 | 4″ | 98 | 153 | 98 | 52 | 163 |

| 4M-BF-LV-125 | 125 | 5″ | —- | —- | —- | —- | — |

| 4M-BF-LV-150 | 150 | 6″ | 148 | 193 | 122 | 57 | 218 |

| 4M-BF-LV-200 | 200 | 8″ | 196 | 223 | 167 | 63 | 273 |

| 4M-BF-LV-250 | 250 | 10″ | —- | —- | — | —- | —- |

| 4M-BF-LV-300 | 300 | 12″ | 291 | 271.5 | 244.5 | 78 | 380 |

High Performance Butterfly Valve

High performance butterfly valves are a type of rotary valve that uses a rotating disk to control flow through a pipe. The disk is generally operable through 90 degrees and provides a linear flow characteristic. For throttling control applications, one type of butterfly valve is now the industry standard: high-performance butterfly valves or double offset valves. Their advantages include a straight-through flow path, very high capacity, and the ability to pass solids and viscous media. High performance butterfly valve (also known as a double offset butterfly valve) features an innovative design that offers rugged reliability and extremely easy maintenance in the field. Independent and internal tests prove the valve’s superior service life capability with zero leakage shutoff.