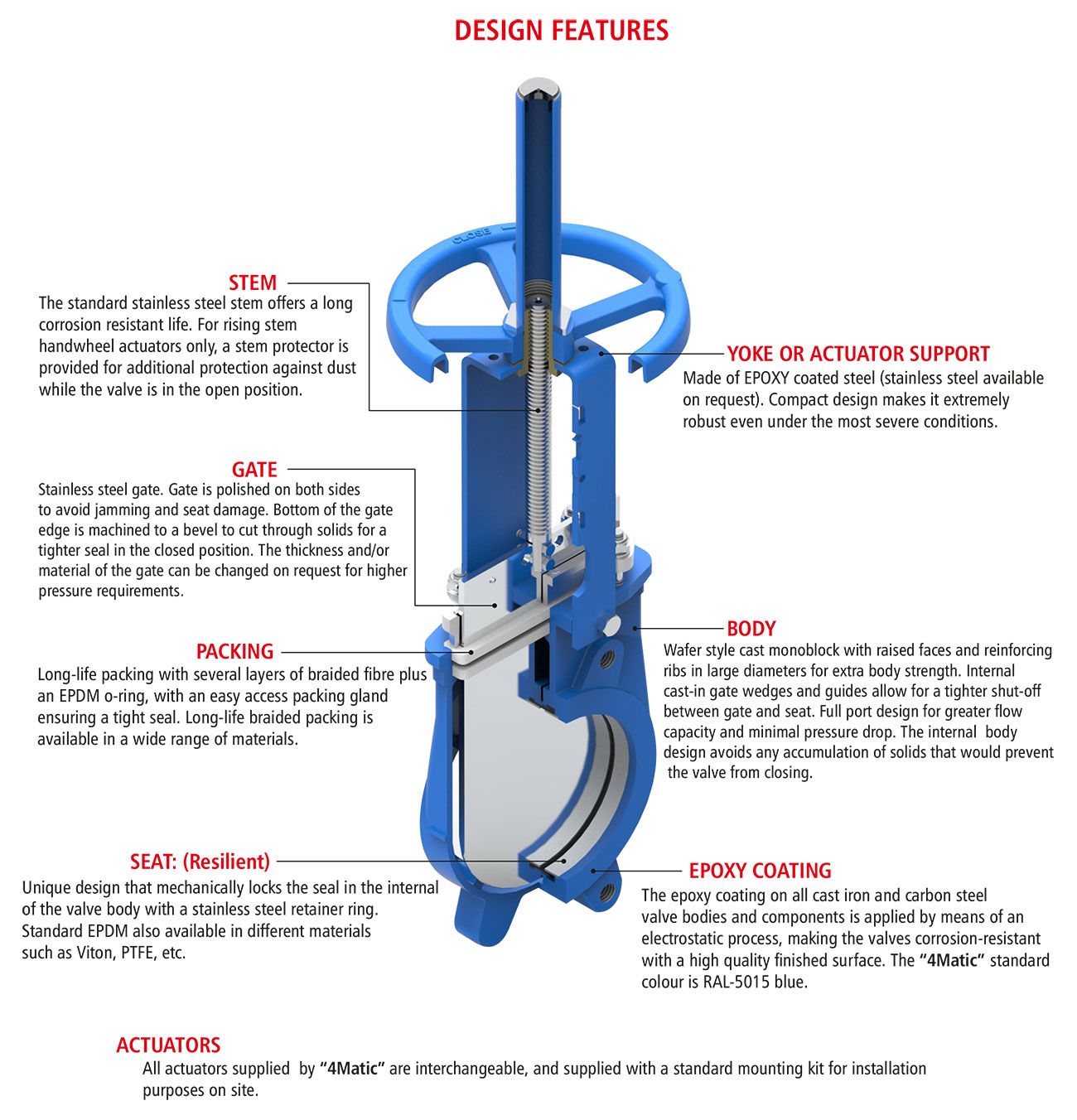

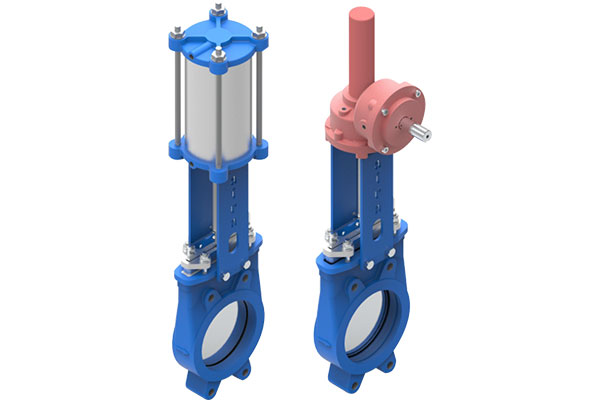

4MAX-SERIES-20 -WAFER SEMI LUG STYLE KNIFE GATE VALVE

The 4MAX(SER-20) model knife gate valve is a uni-directional valve designed for general industrial service applications. The design of the body and seat assures non-clogging shut off on suspended solid in industries such as:

- Pulp and Paper

- Power Plants

- Wastewater Treatment Plants

- Chemical Plants

- Food and Beverage

- Bulk Handling

- Mining

Size Range : DN 50 to DN 1200 (larger diameters on-request)

Working pressure:

| DN 50mm to DN 250mm | 10 bar |

| DN 300mm to DN 400mm | 6 bar |

| DN 450mm | 5 bar |

| DN 500mm to DN 600mm | 4 bar |

| DN 700mm to DN 1200mm | 2 bar |

Working pressure:

DIN PN 10 and ANSI B16.5 (class 150)

Other range connections available on request

DIN PN 6 DIN PN 16 DIN PN 25

BS Table “D” and “E” ANSI 125

All valves are tested prior to shipping in accordance with the standard developed by the Quality Control Department.

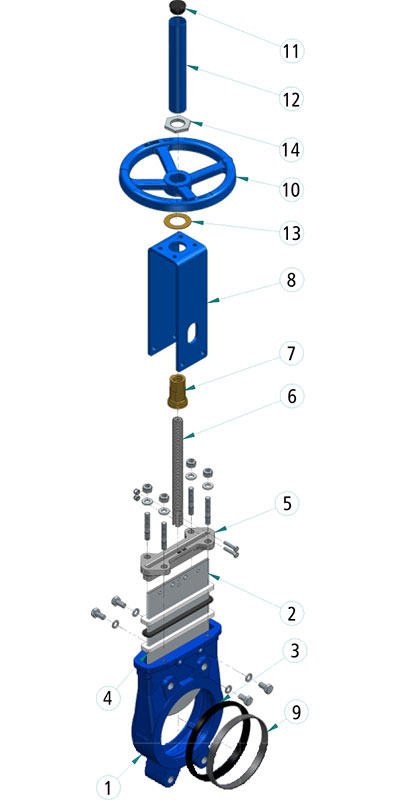

| STANDARD PARTS LIST | |||

| No. | Part | Material | Qty. |

| 1 | Body | ASTM A 536 GR.65-45-12 | 1 |

| 2 | Gate | S.S. 304/316/316L | 1 |

| 3 | Seat | Metal To Metal Or EPDM | 1 |

| 4 | Gland Packing Gasket | PTFE Impregnated Synthetic Fiber/Graphite | 2 |

| 5 | Gland | Aluminum/ASTM a 536 Gr. 65-45-12 | 1 |

| 6 | Stem | S.S. 304/316/316L | 1 |

| 7 | Sleeve | Brass | 1 |

| 8 | Bracket | M.S/S.S | 1 |

| 9 | Ring | S.S. | 1 |

| 10 | Hand Wheel | C.I/S.G.I. | 1 |

| 11 | Bush For Pipe | Plastic/Nylon | 1 |

| 12 | Pipe | M.S. | 1 |

| 13 | Washer | Brass | 1 |

| 14 | Sleeve Lock Nut | M.S/S.S | 1 |

TEMPERATURE CHART

| Material | Max.T (_ºF) | (_ºC) | Applications |

| Metal/Metal | >482 | >250 | High temp./Low tightness |

| EPDM (E) | 248 | 120 | Acids and non mineral oils |

| Nitrile (N) | 248 | 120 | Resistance to petroleum products |

| Viton (V) | 392 | 200 | Chemical service/High temp. |

| Silicone (S) | 482 | 250 | Food service/High temp. |

| PTFE (T) | 482 | 250 | Corrosion resistance |

-> More details and other materials on request

| STANDARD PARTS LIST | |||

| Material | Max.T (_ºF) | (_ºC) | pH |

| Dry cotton (AS) | 122 | 50 | 6 – 8 |

| PTFE impregn. synth. fibre (ST) | 464 | 240 | 2 – 13 |

| Braided PTFE (TH) | 500 | 260 | 0 – 14 |

| Graphited (GR) | 1112 | 600 | 0 – 14 |

| Ceramic fibre (FC) | 2192 | 1200 | — |

NOTE : all types include an elastomere O-ring (same material as seal), excluding TH, GR and FC.

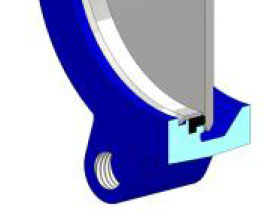

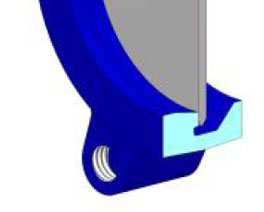

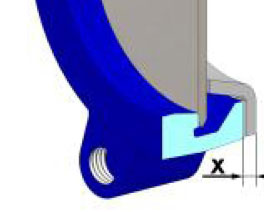

SEAT TYPES

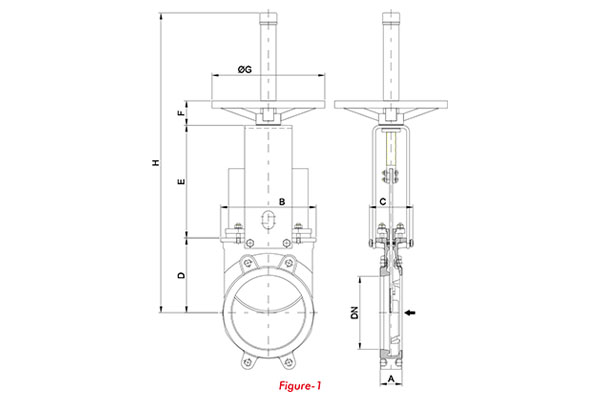

HANDWHEEL (Rising Stem)

Standard manual actuator

• Consists of :

– Handwheel : Epoxy coated Cast Iron

– Stem

– Stem nut

– Stem protector

• Available from DN 50 to DN 1000

Options :

– Locking Device

– Extensions

| DN (mm/inch) | A | B | C | D | E | F | ØG | H | Weight (kg.) |

| 50 (2″) | 40 | 119 | 100 | 105 | 129 | 47 | 225 | 420 | 7 |

| 65 (2.1/2″) | 40 | 134 | 100 | 115 | 146 | 47 | 225 | 450 | 8 |

| 80 (3″) | 50 | 149 | 100 | 124 | 162 | 47 | 225 | 475 | 9 |

| 100 (4″) | 50 | 169 | 100 | 140 | 187 | 47 | 225 | 520 | 11 |

| 125 (5″) | 50 | 180 | 100 | 150 | 211 | 47 | 225 | 600 | 15 |

| 150 (6″) | 60 | 210 | 100 | 175 | 237 | 47 | 225 | 652 | 18 |

| 200 (8″) | 60 | 262 | 119 | 205 | 309 | 67 | 310 | 822 | 30 |

| 250 (10″) | 70 | 318 | 122 | 250 | 364 | 67 | 310 | 1022 | 44 |

| 300 (12″) | 70 | 372 | 122 | 300 | 414 | 67 | 310 | 1122 | 58 |

| 350 (14″) | 96 | 431 | 197 | 338 | 486 | 66 | 410 | 1323 | 96 |

| 400 (16′) | 100 | 486 | 197 | 392 | 536 | 66 | 410 | 1427 | 124 |

| 450 (18″) | 106 | 540 | 201 | 432 | 588 | 66 | 550 | 1594 | 168 |

| 500 (20″) | 110 | 602 | 201 | 485 | 648 | 66 | 550 | 1707 | 192 |

| 600 (24″) | 110 | 708 | 201 | 590 | 748 | 66 | 550 | 2022 | 245 |

| 700 (28″) | 110 | 834 | 380 | 686 | 890 | 74 | 800 | 2778 | 405 |

| 750 (30″) | 110 | 884 | 380 | 760 | 945 | 74 | 800 | 2900 | 455 |

| 800 (32″) | 110 | 1015 | 320 | 791 | 989 | 74 | 800 | 2980 | 512 |

| 900 (36″) | 110 | 1040 | 320 | 895 | 1118 | 74 | 800 | 3215 | 680 |

| 1000 (40″) | 110 | 1146 | 320 | 975 | 1220 | 74 | 800 | 3400 | 865 |