“4Matic” offers disc check valve (wafer type) especially for chemical, Food processing, Pharmaceuticals, Pulp and Paper, Textiles, Power generation, Refrigeration & Air Conditioning etc. The valves are used in Oil lines, Processing line, Hot and cold water systems, steam and condensates, Gas lines etc.

Size Range : 1/2″ to 4″ Screwed

Size Range : 1/2″ to 12″ Wafer Type

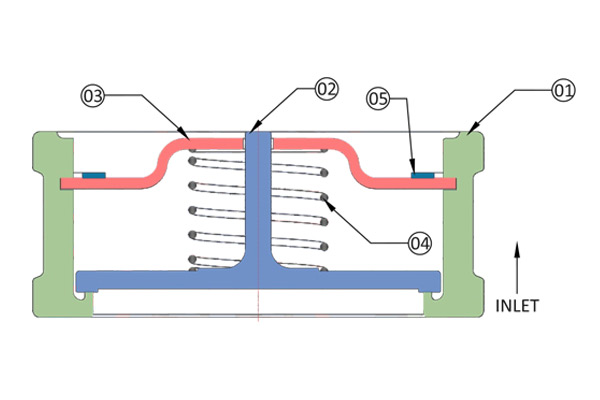

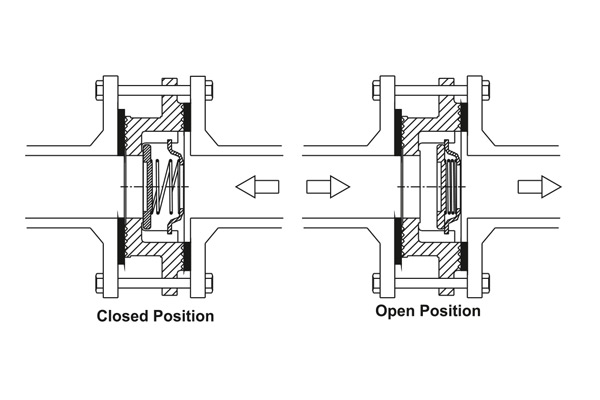

Operation

Disc Check Valves are opened by the pressure of the fluid and closed through compression spring a soon as flow stops thus preventing reverse flow.

Standard

Designed and Manufactured in accordance with BS 7438

Silent Features

- Disc Check Valve is an advance design which gives full flow and occupy very less space than other type of Non Return Valve. This also available IBR Certificate in Form III C.

- DCVs are simple to fit between tow pipe flanges.

- Spring loaded disc to prevent reverse flow in pipe lines.

- Compact Design of Valves flexibly accommodates various types of flange selection.n Stronger, lighter and smaller than conventional swing check valves, hence less expensive to install and maintain.

- The valves can be fitted in any plane / direction in pipe lines.

- Available in 15 mm to 300 mm sizes

- Extremely low operating pressure.

- Self centering type design.

- Zero leakage for soft seated valves

- Testing : As per API 598.

| This Specification Wafer Type DCV | |||

| No. | Description | Material | Qty. |

| 01 | Body | WCB / CF8 / CF8M | 01 |

| 02 | Disc | CF8M | 01 |

| 03 | Retainer | CF8 / CF8M | 01 |

| 04 | Spring | S. S. 304 / 316 | 01 |

| 05 | Stopper | CF8 | 01 |

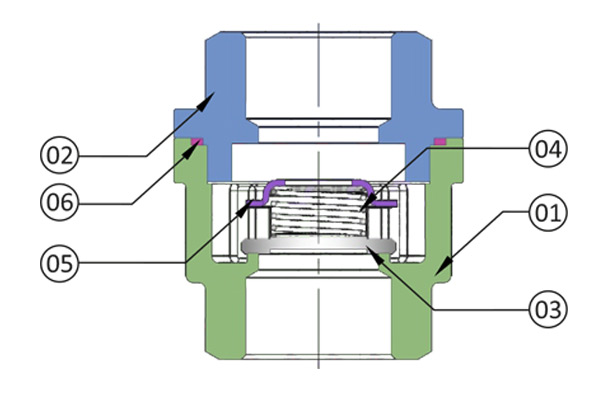

| This Specification Size 1/2″ to 1″ S/E | |||

| No. | Description | Material | Qty. |

| 01 | Body | CF8 / CF8M | 01 |

| 02 | Connector | CF8 / CF8M | 01 |

| 03 | Disc | S. S. 304 / 316 | 01 |

| 04 | Spring | Spring Steel | 01 |

| 05 | Retainer | S. S. 304 | 01 |

| 06 | Body Seal | PTFE | 01 |

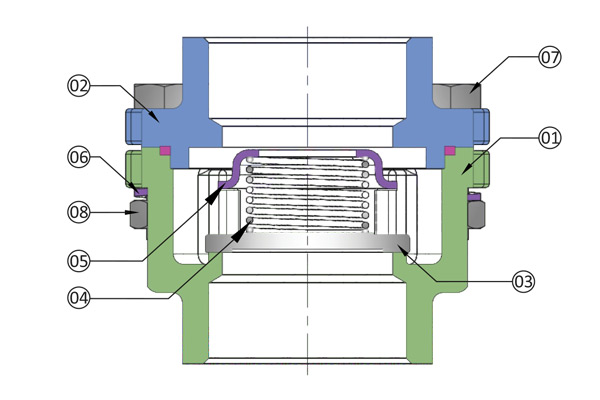

| This Specification Size 1.1/4″ to 2″ Lug Type Design | |||

| No. | Description | Material | Qty. |

| 01 | Body | CF8 / CF8M | 01 |

| 02 | Connector | CF8 / CF8M | 01 |

| 03 | Disc | S. S. 304 / 316 | 01 |

| 04 | Spring | Spring Steel | 01 |

| 05 | Retainer | S. S. 304 | 01 |

| 06 | Body Seal | PTFE | 01 |

| 07 | Hex Bolt | S. S. 304 | 04 |

| 08 | Hex Nut | S. S. 304 | 04 |

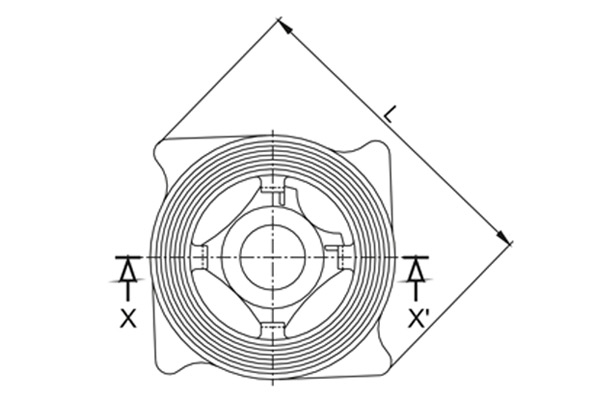

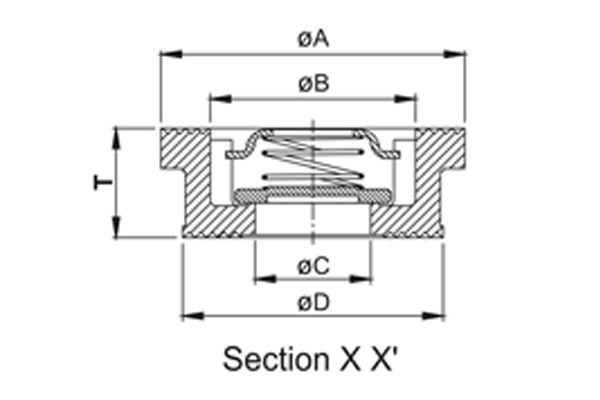

| Dimensions : (All Dimensions are in mm) | |||||||||

| Model | Valve Size | ØA | ØB | ØC | ØD | T | L | Weight Wafer Type |

|

| MM | Inch | ||||||||

| 4M-DNRV – 15 | 15 | 1/2″ | 43 | 29 | 15 | 37 | 16 | 60 | 0.115 |

| 4M-DNRV – 20 | 20 | 3/4″ | 53 | 35 | 20 | 44 | 19 | 70 | 0.183 |

| 4M-DNRV – 25 | 25 | 1″ | 63 | 44 | 25 | 55 | 22 | 80 | 0.284 |

| 4M-DNRV – 32 | 32 | 1.1/4″ | 74 | 53 | 32 | 67 | 28 | 90 | 0.489 |

| 4M-DNRV – 40 | 40 | 1.1/2″ | 85 | 66 | 39 | 78 | 32 | 101 | 0.650 |

| 4M-DNRV – 50 | 50 | 2″ | 95 | 77 | 49 | 92 | 40 | 115 | 1.088 |

| 4M-DNRV – 65 | 65 | 2.1/2″ | 115 | 98 | 64 | 107 | 46 | 142 | 1.200 |

| 4M-DNRV – 80 | 80 | 3″ | 133 | 110 | 79 | 127 | 50 | 153 | 1.700 |

| 4M-DNRV – 100 | 100 | 4″ | 155 | 129 | 100 | 142 | 60 | 184 | 2.550 |

| 4M-DNRV – 125 | 125 | 5″ | 192 | 161 | 125 | 184 | 90 | 245 | 7.600 |

| 4M-DNRV – 150 | 150 | 6″ | 223 | 191 | 150 | 223 | 105 | —- | 9.400 |

| 4M-DNRV – 200 | 200 | 8″ | 279 | 249 | 198 | 279 | 143 | —- | 15.900 |

| 4M-DNRV – 250 | 250 | 10″ | 340 | 306 | 250 | 338 | 140 | —- | 29.100 |

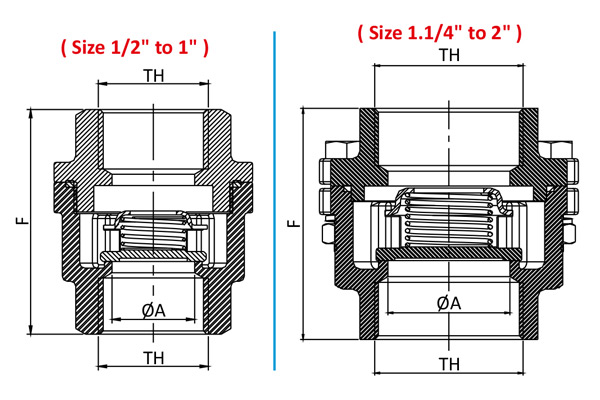

| Dimensions (All Dimensions are in mm) | ||||||

| Valve Model | Valve Size | F | TH | ØA | Weight | |

| MM | Inch | S / E | ||||

| 4M-DNRV – 15 – SD | 15 | 1/2″ | 55 | 1/2″ | 15 | 0.400 |

| 4M-DNRV – 20 – SD | 20 | 3/4″ | 60 | 3/4″ | 20 | 0.640 |

| 4M-DNRV – 25 – SD | 25 | 1″ | 68 | 1″ | 25 | 0.955 |

| 4M-DNRV – 32 – SD | 32 | 1.1/4″ | 76 | 1.1/4″ | 32 | 1.425 |

| 4M-DNRV – 40 – SD | 40 | 1.1/2″ | 81 | 1.1/2″ | 38 | 1.972 |

| 4M-DNRV – 50 – SD | 50 | 2″ | 93 | 2″ | 49 | 2.666 |

Operating Pressure : in m bar Diffferential Pressure With Zero Flow

| 15 MM | 20 MM | 25 MM | 40 MM | 50 MM | 65 MM | 80 MM | 100 MM | 125 MM | 150 MM | 200 MM | 250 MM | |

| ↑ | 25 | 25 | 25 | 28 | 29 | 30 | 31 | 33 | ON REQUEST | |||

| → | 22.5 | 22.5 | 22.5 | 24.5 | 24.5 | 25 | 25.5 | 26.5 | ON REQUEST | |||

| ↓ | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ON REQUEST | |||

→ Indicates Flow Direction

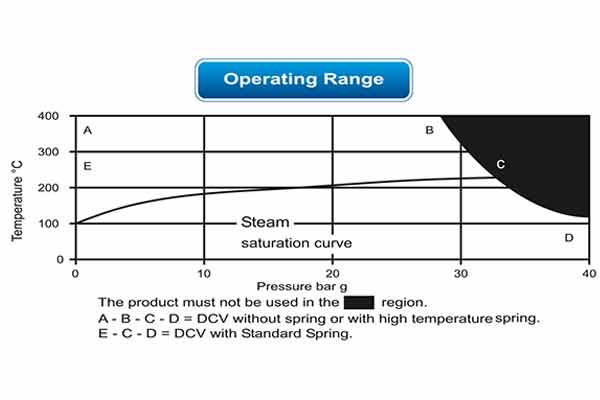

The Valves can be installed, without spring in vertical pipe line with bottom to top flow, Where lowest opening pressures are required .

Without Spring

| 15 MM | 20 MM | 25 MM | 40 MM | 50 MM | 65 MM | 80 MM | 100 MM | 125 MM | 150 MM | 200 MM | 250 MM | |

| ↑ | 2.5 | 2.5 | 2.5 | 3.5 | 4 | 4.5 | 5.5 | 6.5 | ON REQUEST | |||

→ Indicates Flow Direction