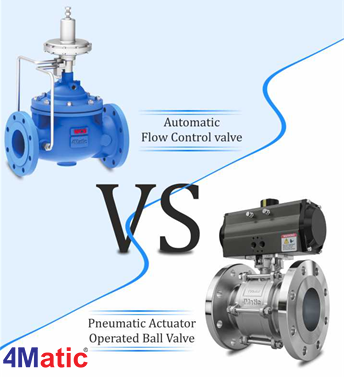

From heating and air-conditioning systems to industrial plants and water distribution systems, valves play a pivotal role as crucial constituents in numerous fluid control systems. There are various kinds of valves but two of the most customers are Regulating valves and On/Off valves. To have a sound understanding with regard to their applications and advantages, we hereby survey the characteristics and benefits of each of these valves.

Features of the Regulating Valves:

Diaphragm Actuator Operated Control Valve

Regulating valves or in other words Control valves are useful to modify and regulate or control the flow of fluids or gases in a system. These valves are tailor made to render perfect control of the volume of flow passing through them.

Regulating valves enable the flow to be adapted in accordance to different levels, which makes these valves perfect tools for the conditions which require perfect regulation, which is not viable in case of On/Off valves.

⇒ Precision and Regulation: Regulating valves are well-known due to their capacity to furnish with the perfect flow control. This is because of their design and peculiar characteristics, for instance, an actuator which enables adjusting the valve opening in distinct positions. This refining ability enables the flow to be controlled as per the requirements of the system, ensuing more perfect and effective control.

⇒ Flexibility: As Regulating valves are very flexible, they have the adaptability to cope up with all sorts of different operating conditions. As for their working capacity is concerned, they can operate over a sizable range of flow rates and pressures and therefore they prove viable for various applications pertaining to commerce and industries. To add to this, Regulating valves have a resistance power to cope up with the changes in system load and therefore can automatically modify to keep up the required flow rate.

⇒ Steadiness: Stability in flow control is also a prime feature of Regulating valves because of their perfection in adjustability. Pressure and flow fluctuations can be automatically compensated through these valves and as such steady output is maintained. This is vital, more particularly in systems which require continuous observance so as to rest assure maximum output.

Features of On/Off Valves :

On/Off Valves, also famous as All-or-Nothing Valves are a kind of valves which have only two states i.e., fully open or fully closed. Where there is a necessity of either full flow or of total flow stoppage, these valves are largely made use of in such applications.

⇒ Easiness: Simplicity or ease of use is the major benefit of On/Off valves. As these valves have two-position design, their operation is simple and are easy to maintain. As these valves do not need precision in adjustments as well as there is no complexity in controls, their installation becomes very easy and makes them viable for usage in different systems.

⇒ Cost Effective: As for the cost is concerned On/Off valves are less expensive as compared to Regulating valves. On/Off valves do not need any advanced mechanism for flow control and as such they become very reasonable as far as their production and maintenance is concerned and therefore, they prove to be very cost effective choice for applications where precision for flow control is not a must.

⇒ Reliableness: Simple design makes On/Off valves more reliable. Due to only two positions in these valves, the chances of failure or leakage is lesser as compared to Regulating valves, which have more complexities. Therefore, in applications, where there is a need of reliable and safe operation, On/Off valves are the perfect option.

⇒ Tight Shut-off: When fully closed, On/Off valves enable tight shut-off which results into total stoppage of leakage and/or contamination of fluid in the system. This is vital, more particularly in applications where hazardous substances are in operation or in systems where it is necessary to have perfect flow control to prevent losses.

Differentiation and Right Selection of Valves:

The selection between Control valves, i.e., Regulating valves and On/Off valves relies upon the particular requirements of the application. Both the types of valves provide different benefits and their viability is also for different conditions.

Where there is a need of perfect flow control, the most viable choice is Regulating valve. These valves provide perfect and steady flow control. Therefore, they are considered the best in applications which require continuous control and prime adjustments.

On the contrary, an On/Off valve is the most feasible choice, where the application needs an easy opening or closing the flow totally. On/Off valves are simple to operate, less expensive and are fully dependable in applications where there is no need for perfect flow control.

In a nutshell, it can be stated that when perfect flow control is required, Regulating valve is the best and viable option, while On/Off valve is the right choice where application requires easy and dependable operation. The right selection will rely on the particular requirements of each system and the vitality of flow control..

To Sum Up….

Regulating valves and On/Off valve, both have a vitality in their own way as far as their role in industrial as well as commercial applications. Both have their own different features and benefits.

Precise control, flexibility and stability in flow control are the functional advantages as far as Regulating valves are concerned and therefore, these valves are most viable when a perfect and continuous control of the flow of fluids or gases is essential.

While as for the functional advantages of On/Off valves are concerned, these valves have easy operation, cost effectiveness as well as dependability and therefore, they are most feasible where there is need of complete opening or closing of the flow.

In the end, it can be stated that, the selection between these valves will rely on the particular requirements of each system. It is crucial to precisely analyze the flow control prerequisites, functional ease and cost effectiveness prior to choosing the most viable valve for a particular application.