4MRPS Series Pilot Operated PRV

4Matic Pilot Operated Pressure Reducing Valve is basically designed for the applications where there is a need to reduce the high level inlet pressure to a safe and consistent level of pressure as per the requirement of a particular application. Following figure displays three main constituents of Pilot Operated PRV.

⇒ Body : Built from top quality materials to rest assure long life performance and resistance against corrosion, the body forms the primary structure of the valve, which houses all the internal components.

⇒ Bonnet : The bonnet covers and safeguards the internal parts of the valve. It is easily removable for maintenance and

inspection purposes, ensuring minimum downtime.

⇒ Diaphragm : The diaphragm keeps the valve in place, so as to ensure secure and steady operation. It is engineered to maximize reliability as well as durability.

Silent Features

⇒ Pipeline breakage because of high pressure can be prevented through the use of 4Matic Pressure Reducing Valve.

⇒ Through the installation of 4Matic Pressure Reducing Valve in the water supply pipeline, the outlet pressure is maintained, regardless of the different inlet pressure.

⇒ High grade materials and robust design, provides durability to the PRV.

⇒ Adaptability as far as sealing options are concerned. NBR EPDM, other material on request.

⇒ Corrosion resistance is enhanced due to Epoxy Coating.

Technical Specifications :

⇒ PRESSURE ADJUSTING RANGE

⇒ TEMPERATURE RATING

⇒ SURFACE COATING : Surface coating through Epoxy provides excellent protection against corrosion, which results into durability of valve even in harsh environments.

⇒ FLANGE DRILLING : Customized flange drilling as per the requirement of the client.

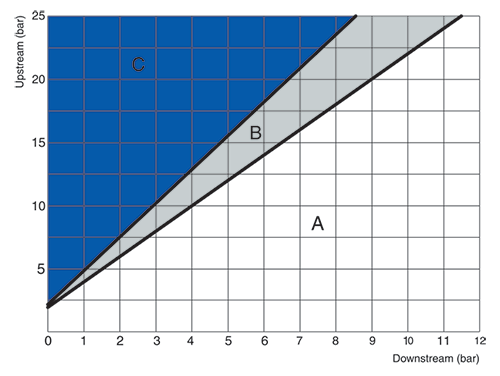

Cavitation Chart :

Cavitation analysis is crucial to avoid significant damage, vibration, and noise. Use a cavitation chart to determine if the working point, based on upstream and downstream pressure conditions, falls into one of three zones:

A: Recommended Operating Conditions

B: Noise Cavitation

C: Damage Cavitation

The chart is applicable for valves modulating at 35-40% opening, at standard water temperature, and below 300 m elevation.

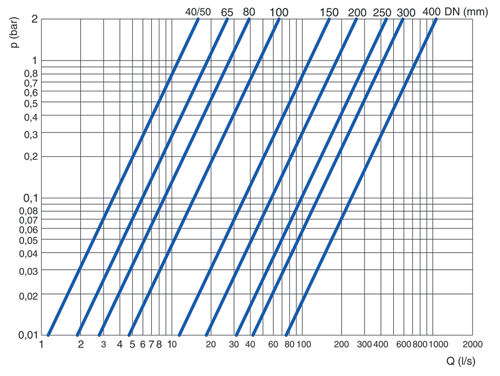

Head Loss Chart :

The chart indicates the head loss of valves fully open versus flow rate in liter per second.

Why Choose 4Matic PRVs?

The 4Matic Pilot Operated PRV isn’t just a valve it’s a commitment to safety, reliability, and innovation. Whether you’re operating in water distribution, industrial processing, or critical infrastructure, this valve delivers unmatched performance tailored to your needs.

Applications:

⇒ Water Distribution Systems: Ensures pressure regulation for efficient water flow.

⇒ Industrial Pipelines: Safeguards systems in chemical plants, oil & gas refineries, and beyond.

⇒ Critical Infrastructure: Provides reliable pressure management in high-stakes operations.