A 4MNEP Series Steam Separator removes suspended water droplets from steam to increase its dryness, typically before a turbine. A 4MNBI Series Steam Trap removes condensate (collected water) and non-condensable gases from steam lines to prevent issues like water hammer and ensure system effciency. Separator use physical methods like centrifugal force or baffles, while traps are automated valves that discharge collected condensate.

4MNEP Series Steam Separator Features

⇒ The 4MNEP Series Steam Separator significantly improves steam dryness by efficiently removing suspended water droplets.

⇒ Its advanced design utilizes centrifugal force, baffles, and vortex action to ensure high-efficiency moisture separation.

⇒ Installed in steam lines to treat steam before it reaches downstream equipment such as turbines, heat exchangers, and process units.

⇒ Protects critical equipment, including turbine blades, from moisture-related damage and extends service life.

⇒ For maximum system efficiency, the steam separator is commonly used in combination with a 4Matic steam trap, where the separator collects water droplets and the trap safely discharges condensate.

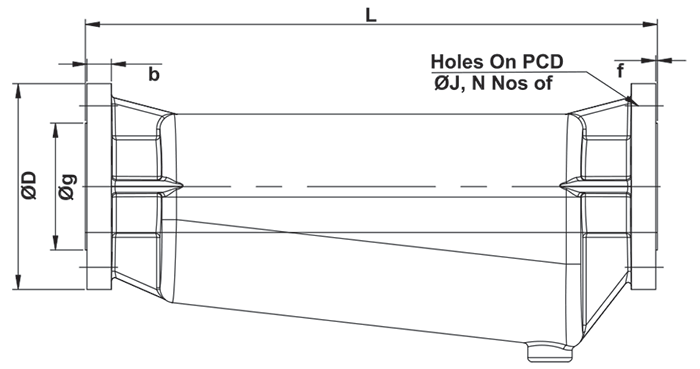

Drawing

Specification

♦ Material : S.G iron / WCB / CF8 / CF8M

♦ Temperature : 350°C

♦ Pressure Rating : As per 150# & 300#

| Size | Port | L | ØD | B | F | Øg | ØJ | N | PCD |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 50 | 465 | 150 | 20.7 | 2 | 92.1 | 9.05 | 04 | 120.7 |

| 65 | 64 | 470 | 180 | 23.9 | 2 | 104.8 | 19.05 | 04 | 139.7 |

| 80 | 78 | 496 | 190 | 27.1 | 2 | 127 | 19.05 | 04 | 152.4 |

| 100 | 99.5 | 708 | 230 | 30.2 | 2 | 157.2 | 19.05 | 04 | 190.5 |

4MNBI Series Steam Trap Features

⇒ The 4MNBI Series Steam Trap automatically removes accumulated condensate and non-condensable gases from steam lines.

⇒ Intelligent automatic operation—opening for condensate discharge and tightly closing for live steam to minimize energy loss.

⇒ Installed at low points in steam pipelines or near steam-using equipment for efficient condensate collection.

⇒ Effectively prevents water hammer, corrosion, and unwanted pressure drops within the system.

⇒ An essential component in 4Matic steam systems, the steam trap safely discharges condensate removed by the steam separator, ensuring reliable and efficient operation.

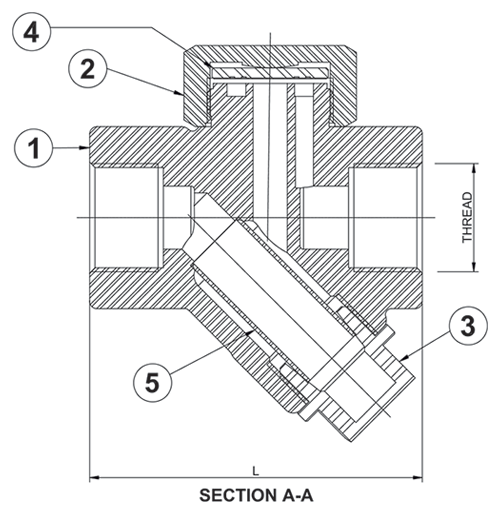

Drawing

| No. | Description | Material |

|---|---|---|

| 1 | Body | CF8 / CF8M |

| 2 | Top Plug | CF8 / CF8M |

| 3 | Bottom Plug | CF8 / CF8M |

| 4 | Washer | S.S / EN 31 |

| 5 | Strainer | S.S |

| Size | L | BSP / NPT |

|---|---|---|

| 15 | 77.5 | 15 |

| 20 | 77.5 | 20 |

| 25 | 92.4 | 25 |

| Tolerance ±3MM | ||