“4Matic” Offers Pneumatic Actuator Operated Metal Seated Floating Ball Valve designed for using in the several conditions such as high temperature & high friction fluid like abrasive fluids of Oil & Gas, Petroleum, Petrochemical, Chemical Power Generation, Pulp & Paper, Mining Industry

Size Range : 1/2″ to 4″ Screwed / Flanged

| Standard | |

| Design And Manufacturing | BS EN ISO 17292 / ASME B16.34 |

| Valve Face To Face Dimension | ASME B 16.10 |

| Flange Standard Conformity | ASME B 16.5 Class 150# / 300# / 600# |

| Inspection & Testing | API 598 / ISO – 5208 |

| Leakage Class | Class IV to V |

Accessories

- On / OFF Indicator

- NAMUR Standard Solenoid Valve in all Standard Coil Voltage (Flame Proof Solenoid Coil – On Request)

- Pneumatic & Electro-Pneumatic valve positioner

- Declutchable Manual Over – Ride

- Limit Switches for On / Off Indication at Panel Board

- Filter + Regulator Combination with Pressure Gauge

- Air Lock Valve

Extra Coating Details On Ball & Ball Seat

| Coating Material | Maximum Temperature |

| Tungsten Carbide (WC-CO) | -200°C to 450°C ( On Request) |

| Tungsten Chromium Carbide (WC-COCRC) | -50°C to 300°C ( On Request) |

| Chromium Carbide (Cr7C3+25%NICr) | -200°C to 800°C ( On Request) |

| Hard (Trivalent Chromium) (HCr) | -50°C to 450°C ( On Request) |

| Nickle Chrome Boron Silica (NiCrBSi) | -200°C to 700°C ( On Request) |

| Electroless Nickel Plating (ENP) | -50°C to 450°C ( On Request) |

| Stellite – 6 (CoCrWC) | 1200°C ( On Request) |

| Nitriding & Lapping | 450°C ( Regular ) |

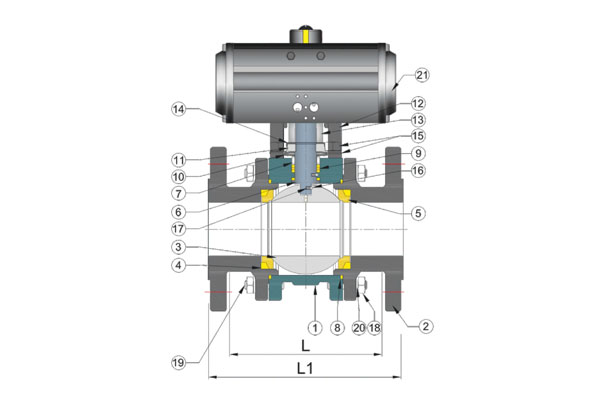

Screwed Dimensions :

| Valve Model | Valve Size | L | Weight Approx. | |

| Inch | MM | |||

| 4M-BMS – 15 | 1/2″ | 15 | 71 | 3.700 |

| 4M-BMS – 20 | 3/4″ | 20 | 94 | 4.700 |

| 4M-BMS – 25 | 1″ | 25 | 108.5 | 6.500 |

| 4M-BMS – 32 | 1.1/4″ | 32 | 116 | 7.200 |

| 4M-BMS – 40 | 1.1/2″ | 40 | 128 | 8.500 |

| 4M-BMS – 50 | 2″ | 50 | 158 | 13.850 |

| 4M-BMS – 65 | 2.1/2″ | 65 | 185 | 20.700 |

| 4M-BMS – 80 | 3″ | 80 | 205 | 29.200 |

| 4M-BMS – 100 | 4″ | 100 | 239 | 43.900 |

(All Dimensions are in mm)

Flanged Dimensions :

| Valve Model | Valve Size | L1 | Weight Approx. | |

| Inch | MM | |||

| 4M-BMF – 15 | 1/2″ | 15 | 108 | 4.350 |

| 4M-BMF – 20 | 3/4″ | 20 | 117 | 5.950 |

| 4M-BMF – 25 | 1″ | 25 | 127 | 7.700 |

| 4M-BMF – 32 | 1.1/4″ | 32 | 140 | 8.850 |

| 4M-BMF – 40 | 1.1/2″ | 40 | 165 | 10.650 |

| 4M-BMF – 50 | 2″ | 50 | 178 | 15.000 |

| 4M-BMF – 65 | 2.1/2″ | 65 | 190 | 27.300 |

| 4M-BMF – 80 | 3″ | 80 | 203 | 36.550 |

| 4M-BMF – 100 | 4″ | 100 | 229 | 51.900 |

(All Dimensions are in mm)

Note : Big Sizes 5″ to 10″ On Request. / Note : 300# & 600# Dimension are On Request.

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M / CF3M |

| 2 | Connector | WCB / CF8 / CF8M / CF3M |

| 3 | Ball | CF8 / CF8M / CF3M |

| 4 | Ball Back Seat | CFT |

| 5 | Ball Seat | S.S. 304 / 316 |

| 6 | Stem Pin | S.S. 304 / 316 |

| 7 | Spacer Ring | S.S. 304 / 316 |

| 8 | Body Seat | CFT |

| 9 | Stem Seat | CFT |

| 10 | Disc Spring | Spring Steel |

| 11 | Steam Nut | S. S. 304 |

| 12 | Bracket | WCB / CF8 / CF8M / CF3M |

| 13 | Adaptor | S. S. 304 |

| 14 | Lock Washer | S. S. 304 |

| 15 | Bracket Fitting Hex Bolt + Spring Washer | S. S. 304 |

| 16 | Antistatic Ball | S. S. 304 |

| 17 | Antistatic Spring | S. S. 302 |

| 18 | Fitting Nut | H. T. / S. S. 304 |

| 19 | Fitting Stud | H. T. / S. S. 304 |

| 20 | Spring Washer | H. T. / S. S. 304 |

| 21 | Actuator | STD. |

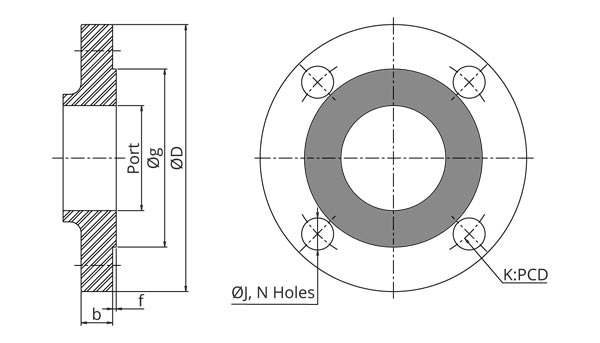

For Ball Valves Flange Standards Dimension Table :

| As Per ASME B16.5 150# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 108 | 90 | 34.9 | 9.6 | 2 | 15.9 | 4 | 60.3 |

| 3/4″ | 20 | 19 | 117 | 100 | 42.9 | 11.2 | 2 | 15.9 | 4 | 69.9 |

| 1″ | 25 | 25 | 127 | 110 | 50.8 | 12.7 | 2 | 15.9 | 4 | 79.4 |

| 1.1/4″ | 32 | 32 | 140 | 115 | 63.5 | 14.3 | 2 | 15.9 | 4 | 88.9 |

| 1.1/2″ | 40 | 38 | 165 | 125 | 73 | 15.9 | 2 | 15.9 | 4 | 98.4 |

| 2″ | 50 | 49 | 178 | 150 | 92.1 | 17.5 | 2 | 19.05 | 4 | 120.7 |

| 2.1/2″ | 65 | 62 | 190 | 180 | 104.8 | 20.7 | 2 | 19.05 | 4 | 139.7 |

| 3″ | 80 | 74 | 203 | 190 | 127 | 22.3 | 2 | 19.05 | 4 | 152.4 |

| 4″ | 100 | 100 | 229 | 230 | 157.2 | 22.3 | 2 | 19.05 | 8 | 190.5 |

| 5″ | 125 | 125 | 254 | 255 | 185.7 | 22.3 | 2 | 22.2 | 8 | 215.9 |

| 6″ | 150 | 150 | 267 | 280 | 215.9 | 23.9 | 2 | 22.2 | 8 | 241.3 |

| 8″ | 200 | 201 | 292 | 345 | 269.9 | 27 | 2 | 22.2 | 8 | 298.5 |

| 10″ | 250 | 252 | 330 | 405 | 323.8 | 28.6 | 2 | 25.4 | 12 | 362 |

| 12″ | 300 | 303 | 610 | 485 | 381 | 30.2 | 2 | 25.4 | 12 | 431.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 300# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 140 | 95 | 34.9 | 12.7 | 2 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 152 | 115 | 42.9 | 14.3 | 2 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 165 | 125 | 50.8 | 15.9 | 2 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 178 | 135 | 63.5 | 17.5 | 2 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 190 | 155 | 73 | 19.1 | 2 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 216 | 165 | 92.1 | 20.7 | 2 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 241 | 190 | 104.8 | 23.9 | 2 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 282 | 210 | 127 | 27 | 2 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 305 | 255 | 157.2 | 30.2 | 2 | 22.2 | 8 | 200 |

| 5″ | 125 | 125 | 381 | 280 | 185.7 | 33.4 | 2 | 22.2 | 8 | 235 |

| 6″ | 150 | 150 | 403 | 320 | 215.9 | 35 | 2 | 22.2 | 12 | 269.9 |

| 8″ | 200 | 201 | 419 | 380 | 269.9 | 39.7 | 2 | 25.4 | 12 | 330.2 |

| 10″ | 250 | 252 | 457 | 445 | 323.8 | 46.1 | 2 | 28.6 | 16 | 387.4 |

| 12″ | 300 | 303 | 648 | 520 | 381 | 49.3 | 2 | 31.75 | 16 | 450.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 600# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 165 | 95 | 34.9 | 14.3 | 7 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 190 | 115 | 42.9 | 15.9 | 7 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 216 | 125 | 50.8 | 17.5 | 7 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 229 | 135 | 63.5 | 20.7 | 7 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 241 | 155 | 73 | 22.3 | 7 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 292 | 165 | 92.1 | 25.4 | 7 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 330 | 190 | 104.8 | 28.6 | 7 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 356 | 210 | 127 | 31.8 | 7 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 432 | 275 | 157.2 | 38.1 | 7 | 25.4 | 8 | 215.9 |

| 5″ | 125 | 125 | 508 | 330 | 185.7 | 44.5 | 7 | 28.6 | 8 | 266.7 |

| 6″ | 150 | 150 | 559 | 355 | 215.9 | 47.7 | 7 | 28.6 | 12 | 292.1 |

| 8″ | 200 | 201 | 660 | 420 | 269.9 | 55.6 | 7 | 31.75 | 12 | 349.2 |

| 10″ | 250 | 252 | 787 | 510 | 323.8 | 63.5 | 7 | 34.9 | 16 | 431.8 |

| 12″ | 300 | 303 | 838 | 560 | 381 | 66.7 | 7 | 34.9 | 20 | 489 |

(All Dimensions are in mm)