4M-TOB Triple Offset Butterfly Valves

4Matic Triple Offset valve is furnished with zero-leak, bi-directional tight shutoff. This is obtained through the use of genuine all-metal construction and as such needs less torque, lesser wear and tear, working longevity, and offers a much tighter shutoff as compared to previous designs. Due to a two-piece shaft construction, higher flow capacities can be obtained and all this is achieved at a low cost for components, ultimately resulting in economizing on maintenance.

Zero Leak Bi-directional Tight Shutoff Proficiencies

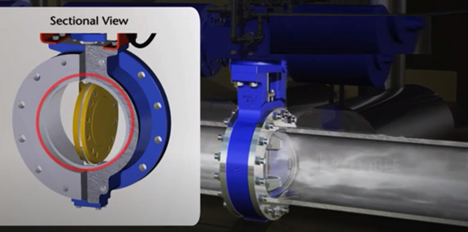

An enhanced disc sealing profile gives better and steady contact along the whole circumference of the seat, paving the way for the new offering to accomplish even the most challenging tightness necessities.

Genuine Metal -to- Metal Sealing: Inventiveness and Dependability

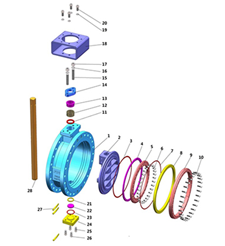

Genuine all metal hard-coated seat ring with no resilient components makes it easy to control abrasive media, dirty service, excessive velocity, high temperature fluctuations and LNG applications. The menace of galvanic corrosion in particular applications because of the occurrence of graphite is done away with.

As there are no fasteners in the path of the flow, the chances for parts and/or material to come into contact and passing downstream, spoiling the equipment, is abolished. Genuine metal-to-metal construction also gives improved performance in the applications which have vibrations and provides quicker stroking times as compared to a standard triple offset solution.

The seat ring complies with and self-aligns to the disc giving repeatable bi-directional sealing execution. The floating seat can move within the seat cavity to facilitate changes in pressures and temperatures. A perfect connection between seat and disc creates a dependable performance of the materials. The occurrence sliding wear is nullified.

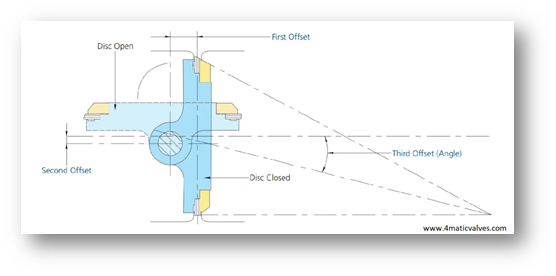

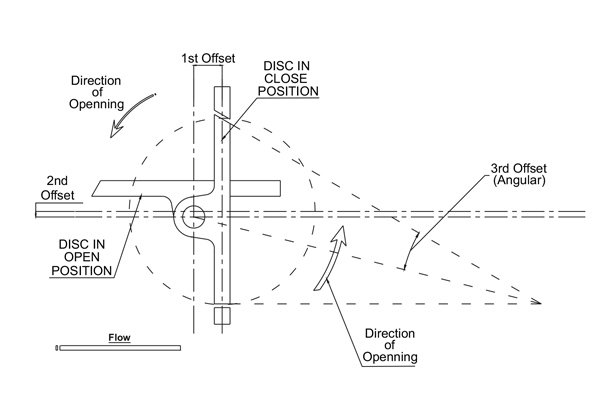

Structural Comparison

Necessity of Low Torque

4M-TOB is a composition of torque seated and position seated conception. An opening torque is put in an application to position the disc for stiff shutoff. Dependable and repeatable shutoff is kept up through this position. The outcome is low torque, which ultimately provides small scale automated packages, reduced actuator air consumption, reduced weight, lower cost and trouble-free installation i.e., piping supports. The requirement of lowered torque also diminishes wear and tear and assists for longer working life.

Enhanced for Effective Flow

4M-TOB Butterfly Valves have been conceptualized to give elevated flow volume so as to have a sizable reduction in energy utilization. In numerous cases the needed flow volume can be reached even while sizing down. This design also gives a greater control range to the tune of 10% to 80%. These valves can also be furnished with an option of through shaft for critical isolation applications.

Trouble-free Maintenance

4M TOB, though the valve is sturdy, its uncomplicated design of single disc and seat makes the maintenance easier and thereby cost effective. Even without disassembling the disc and shaft, the interchangeable seat can be replaced. As for parts replacement, only about 15% requirement is there when this valve is in utility, as compared to other competing solutions.

Fugitive Emissions Reduced to a Minimum

Emission certified packing designs are achievable for all applications; hence a particular construction is not required. Fugitive emissions brought to the minimum is very important not only to be rest assured with regard to the health as well as the safeguarding of personnel but also for the cost-effectiveness and energy productivity of the entire plant. Along with this, the reduction in fugitive emissions is also vital to bring down environmental impact to the minimum.

General information

- Size Range : 2″ to 12″

- Design And Manufacturer : API 609 category A / IS : 13095 / BS EN 593

- Valve Face To Face Dimension : Short Wafer As Per ISO 5752 TAB 5 / API 609 Category A ISO 5752 TAB 1 (BS 5155)

- Flange Standard Conformity : ASME B16.5 / 16.47 Series A Class 150, BS 10 TAB D,E & F

- Inspection & Testing : API 598 / BS EN 12266 – 1

Triple Offset Butterfly Valve with Pneumatic Actuator

- Size : 1½” to 12″

- MOC : Aluminium Alloy

- Seals : Nitrile / NBR / EPDM / Vilton

- Pressure : PN 10 / 16

- Temp. : Upto 180°c

- Ends : Wafer Type

Triple Offset “WAFER TYPE” Butterfly Valve 150# ( Fire Safe Design )

“4Matic” offers Manual Worm Gear / Lever Operated Off – Set Disc Butterfly Valve in Wafer & Double Flange Construction engineered for multiply ON / OFF Operation in the large Pipe line and full flow down Stream.

Size Range : 2″ to 12″ ( 150# )

| PRESSURE / TEMPERATURE RATING | |

| PRESSURE | As Per 150# B16.34 |

| TEMPERATURE | -550 °C ( Above 550 °C On Request ) |

| Standard | |

| Design And Manufacturing | API 609 |

| Valve Face To Face Dimension | API 609 Category “B” |

| Flange Standard Conformity | ASME / ANSI B 16.5 Class 150 |

| Inspection & Testing | API 598 |

| Leakage Class | ASME B 16, 16.104 Leakage Class VI |

| VALVE TORQUE 150# | ||||

| Valve Size | 5 Bar N – m | 10 Bar N – m | 20 Bar N – m | |

| MM | Inch | |||

| 50 | 2″ | 11 | 15 | 21 |

| 65 | 2.1/2″ | 20 | 28 | 38 |

| 80 | 3″ | 38 | 43 | 63 |

| 100 | 4″ | 50 | 58 | 80 |

| 125 | 5″ | 73 | 100 | 144 |

| 150 | 6″ | 113 | 144 | 181 |

| 200 | 8″ | 175 | 219 | 350 |

| 250 | 10″ | 294 | 331 | 375 |

| 300 | 12″ | 400 | 450 | 625 |

| CV Values | ||||||||||

| Valve Size | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| MM | Inch | |||||||||

| 50 | 2″ | 2 | 5 | 11 | 19 | 28 | 41 | 58 | 77 | 85 |

| 65 | 2.1/2″ | 2 | 9 | 20 | 28 | 45 | 60 | 80 | 120 | 130 |

| 80 | 3″ | 3 | 10 | 22 | 42 | 64 | 96 | 150 | 157 | 160 |

| 100 | 4″ | 6 | 17 | 41 | 75 | 116 | 174 | 273 | 284 | 290 |

| 125 | 5″ | 6 | 45 | 75 | 170 | 280 | 478 | 650 | 707 | 795 |

| 150 | 6″ | 7 | 51 | 119 | 221 | 340 | 510 | 799 | 833 | 850 |

| 200 | 8″ | 4 | 103 | 239 | 445 | 684 | 1026 | 1607 | 1676 | 1710 |

| 250 | 10″ | 50 | 151 | 353 | 655 | 1008 | 1515 | 2369 | 2470 | 2520 |

| 300 | 12″ | 79 | 236 | 552 | 1024 | 1576 | 2364 | 3704 | 3861 | 3940 |

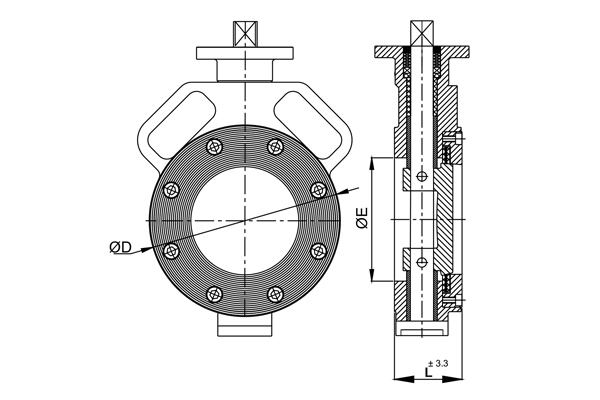

| Dimensions : (All Dimensions are in mm) | |||||

| Valve Model | Valve Size | L | ØD | ØE | |

| MM | Inch | ||||

| 4M-TO-HP-50 | 50 | 2″ | 47 | 95 | 50.8 |

| 4M-TO-HP-65 | 65 | 2.1/2″ | 52 | 108 | 60.6 |

| 4M-TO-HP-80 | 80 | 3″ | 52 | 127 | 72 |

| 4M-TO-HP-100 | 100 | 4″ | 57 | 159 | 100 |

| 4M-TO-HP-125 | 125 | 5″ | 60 | 186 | 123 |

| 4M-TO-HP-150 | 150 | 6″ | 60 | 217 | 143 |

| 4M-TO-HP-200 | 200 | 8″ | 67 | 270 | 192 |

| 4M-TO-HP-250 | 250 | 10″ | 72 | 322 | 239 |

| 4M-TO-HP-300 | 300 | 12″ | 75 | 382 | 290 |