Ball Check Valve (Flanged)

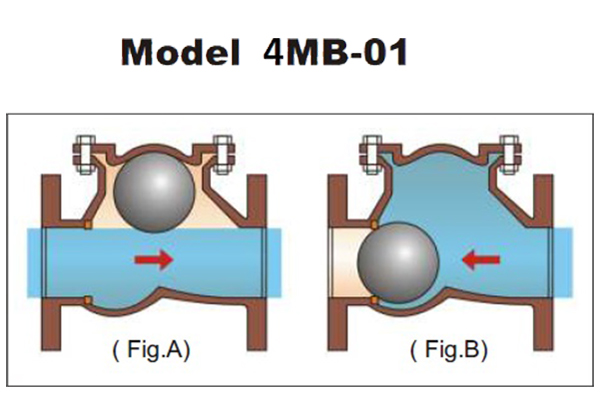

Principle

The reinforced rubber ball is the heart of this valve. This ball in the designed path of the valve moves freely and promptly reacts to the ON & OFF of the pump. The ball moves to open position when the pump starts & allows free flow of liquid without any interference. (Fig. A) As the pump stops, the ball seats firmly against the metal seat due to its own weight & back pressure of the liquid (Fig B) This results in DROPLESS sealing.

Features of the Valve

- New generation valve with unique and non-conventional design.

- Suitable for a very wide range of applications like slurry, sewage, paper, chemical, water supply, agriculture, muddy water, slurry, paper stock, viscous liquid and dear water.

- Robust and very simple mechanism.

- Afloating reinforced rubber coated ball is used instead of hinge-pin-disc.

- Highly sensible to arrest flow with perfect sealing.

- Very low head loss

- Non clogging and self cleaning mechanism

- Maintenance free

- Power saving

- Large solid handling capacity

- Dimensionally conforming with DIN 3202-F6 / EN558-1-S48 / IS 5312

- Installation can be vertically or horizontally

- Operates silently upto 80 °C

- This valve has a quality for withstanding consistent performance and longer

Pressure Rating

| Size | Rating |

| 25 – 125NB | PN 1.6 |

| 150 – 300NB | PN 1.0 |

| 350NB | PN 0.6 |

| For CI Construction | |

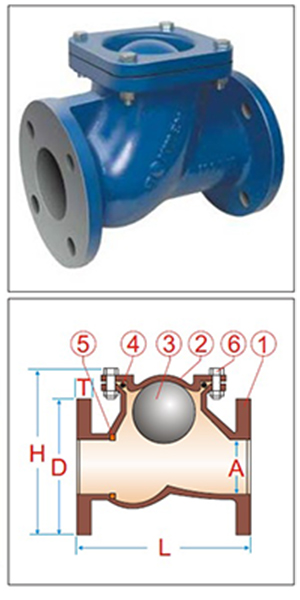

Part List / Materials of Construction

| Part Description | Standard | Special |

|

Cast Iron GG 25 | St. Steel, Cast Steel |

|

Cast Iron GG 25 | St. Steel, Cast Steel |

|

Nitrile Rubbercoated | EPDM, Neoprene |

|

Nitrile ASTM D2000 | Butyle, Viton |

|

L.T.Bronze LTB2 | St. Steel, Hard Rub. |

|

Carbon Steel CL4 | St. Steel |

Dimensions (A = Valve size in mm)

| A | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| D | 115 | 150 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | 445 | 527 |

| L | 144 | 174 | 200 | 240 | 260 | 300 | 350 | 400 | 500 | 600 | 700 | 800 |

| H | 125 | 165 | 185 | 210 | 250 | 285 | 340 | 415 | 505 | 600 | 670 | 835 |

| T | 15 | 15 | 16 | 16 | 20 | 22 | 22 | 24 | 23 | 28 | 28 | 32 |

| Width | 115 | 150 | 166 | 186 | 202 | 221 | 275 | 307 | 375 | 433 | 501 | 535 |

| Wt.(kg) | 4.0 | 6.5 | 9.5 | 13.0 | 19.0 | 28.0 | 46.0 | 60.0 | 103.0 | 156.0 | 209.0 | 310.0 |

Ball Check Valve (Threaded)

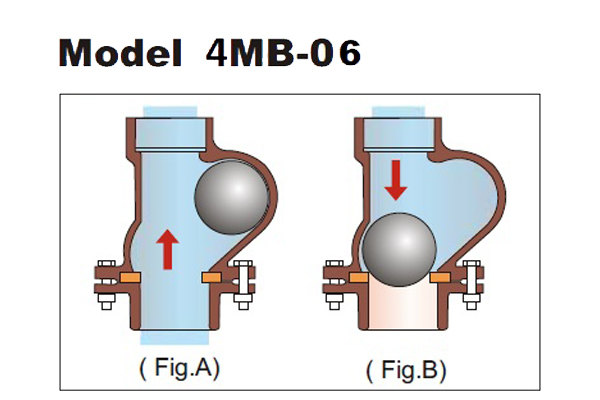

Principle

The reinforced rubber ball is the heart of this valve. This ball in the designed path of the valve moves freely and promptly reacts to the ON & OFF of the pump. The ball moves to open position when the pump starts & allows free flow of liquid without any interference. (Fig. A) As the pump stops, the ball seats firmly against the metal seat due to its own weight & back pressure of the liquid (Fig B) This results in DROPLESS sealing.

Features of the Valve

- New generation valve with unique and non-conventional design.

- Suitable for a very wide range of applications like slurry, sewage, paper, chemical, water supply, agriculture, muddy water, slurry, paper stock, viscous liquid and dear water.

- Robust and very simple mechanism.

- Afloating reinforced rubber coated ball is used instead of hinge-pin-disc.

- Highly sensible to arrest flow with perfect sealing.

- Very low head loss

- Non clogging and self cleaning mechanism

- Maintenance free

- Power saving

- Large solid handling capacity

- Dimensionally conforming with DIN 3202-F6 / EN558-1-S48 / IS 5312

- Installation can be vertically or horizontally

- Operates silently upto 80 °C

- This valve has a quality for withstanding consistent performance and longer

Pressure Rating

| Size | Rating |

| 25 – 100NB | PN 0.6 |

| For CI Construction | |

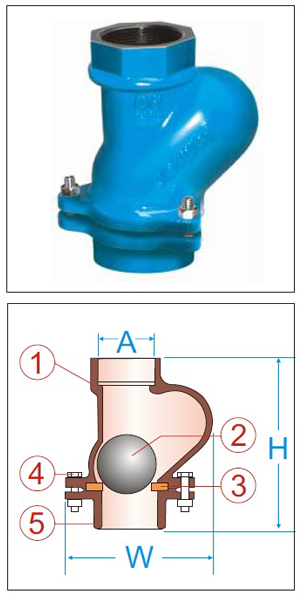

Dimensions (A = Valve size in mm)

| A | 25 | 40 | 50 | 65 | 80 | 100 |

| H | 121 | 142 | 167 | 208 | 250 | 295 |

| W | 115 | 125 | 136 | 165 | 204 | 250 |

| Wt.(kg) | 1.7 | 2.0 | 3.2 | 5.2 | 8.5 | 13.5 |

Part List / Materials of Construction

| Part | Description | Material |

| 1. | Body | Cast Iron – IS210, FG200 (min) |

| 2. | Ball | Nitrile Rubber Coated |

| 3. | Seat Ring | Nitrile ASTM D-2000 |

| 4. | Fastener | Carbon Steel CL4 |

| 5. | Adaptor | Cast Iron – IS210, FG200 (min) |