“4Matic” offers Manual (Gear / Handle) Flanged End Butterfly Valve, engineered for multiple ON/OFF operations in the larger pipe line and full flow down streams.

Size Range : 3″ to 48″

| PRESSURE / TEMPERATURE RATING | |

| PRESSURE | TEMPERATURE |

| PN 10 / PN 16 ( PN 20 ON REQUEST) | -20 to 80 °C For Nitrile Seat Depending On MOC |

Key Feature :

- Integrally moulded seat liner on the body, which ensures excellent dimensional stability & guaranteed seat tightness.

- Seat liner extending on to the contact faces ensures perfect sealing and eliminates the need for separate flange gaskets.

- Narrow land disc ensures perfect sealing with least operating torque requirements.

- A fully universal body design ensures fitting of the valve between companion flanges of all popular standards (viz : ANSI, BS, DIN,JIS, IS etc.)

- The notch disc & band lever ensures locking of the valve in 8 intermediate position in addition to close and open position. Hand lever can be locked through pad lock.

- Body casting made of superior FG 260 grade cast iron to ensure additional strength.

- Valve disc made of stainless steel / ductile cast iron which enable protection against possible water hammer or pressure surges.

- A truly line size body bone to ensure maximum flow capacity with the lowest pressure drop.

| TEST PRESSURE | ||

| TESTING | BODY | SEAT |

| HYDRAULIC | 20 KG/CM2 | 11 KG/CM2 |

| PNEUMATIC SEAT PRESSURE | 6 KG/CM2 | |

| SPARK TEST – 15 KV D. C. | ||

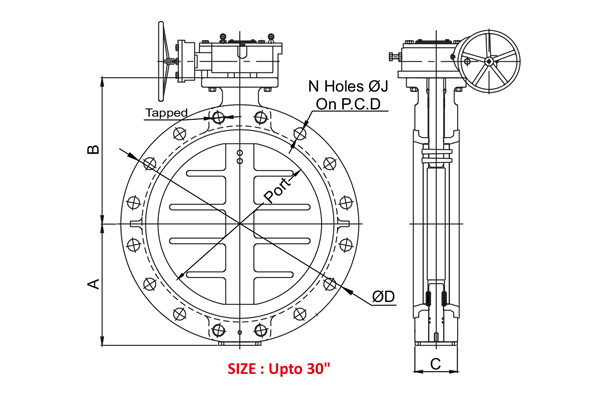

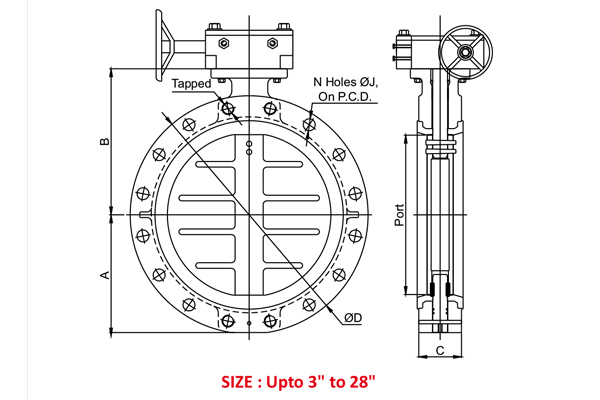

Note : (Valve F to F will be as per Wafer type) (Flange Thickness Non – STD As per Mfg. Std Wafer short Wafer End Body)

| Dimensions : (All Dimensions are in mm) | |||||||||||

| Valve Model | Valve Size | PORT | A | B | C | ØD | N | ØJ | Tapped | PCD | |

| MM | INCH | ||||||||||

| 4M-DF-ECO-80 | 80 | 3″ | 80 | 95 | 129 | 46 | 190 | 4 | 19.05 | – | 152.4 |

| 4M-DF-ECO-100 | 100 | 4″ | 100 | 113 | 147 | 52 | 230 | 8 | 19.05 | — | 190.5 |

| 4M-DF-ECO-150 | 150 | 6″ | 150 | 136 | 177 | 56 | 280 | 8 | 22.2 | — | 241.3 |

| 4M-DF-ECO-200 | 200 | 8″ | 200 | 174 | 214 | 60 | 345 | 8 | 22.2 | — | 298.5 |

| 4M-DF-ECO-250 | 250 | 10″ | 241 | 201 | 265 | 68 | 405 | 12 | 25.4 | — | 362 |

| 4M-DF-ECO-300 | 300 | 12″ | 286 | 236 | 303 | 78 | 485 | 12 | 25.4 | — | 431.8 |

| 4M-DF-ECO-350 | 350 | 14″ | 333 | 248 | 345 | 78 | 535 | 12 | 28.6 | — | 476.3 |

| 4M-DF-ECO-400 | 400 | 16″ | 382 | 300 | 364 | 102 | 595 | 16 | 28.6 | — | 539.8 |

| 4M-DF-ECO-450 | 450 | 18″ | 433 | 322 | 381 | 114 | 635 | 16 | 31.75 | 1″ UNC | 577.9 |

| 4M-DF-ECO-500 | 500 | 20″ | 476 | 354 | 436 | 127 | 700 | 20 | 31.75 | 1″ UNC | 635 |

| 4M-DF-ECO-600 | 600 | 24″ | 590 | 405 | 515 | 154 | 815 | 20 | 34.9 | 1.1/4″ UNC | 749.3 |

| 4M-DF-ECO-650 | 650 | 26″ | 635 | 435 | 490 | 165 | 870 | 24 | 34.9 | 1.1/4″ UNC | 806.4 |

| 4M-DF-ECO-700 | 700 | 28″ | 680 | 462 | 543 | 165 | 925 | 28 | 34.9 | 1.1/4″ UNC | 863.6 |

| 4M-DF-ECO-750 | 750 | 30″ | 725 | 482 | 576 | 190 | 985 | 28 | 34.9 | 1.1/4″ UNC | 914.4 |

| 4M-DF-ECO-800 | 800 | 32″ | 785 | 533 | 618 | 190 | 1060 | 28 | 41.3 | 1.1/2″ UNC | 977.9 |

| 4M-DF-ECO-900 | 900 | 36″ | 885 | 576 | 675 | 203 | 1170 | 32 | 41.3 | 1.1/2″ UNC | 1085.8 |

| 4M-DF-ECO-1000 | 1000 | 40″ | 965 | 640 | 720 | 216 | 1290 | 36 | 41.3 | 1.1/2″ UNC | 1200.2 |

| 4M-DF-ECO-1200 | 1200 | 48″ | 1170 | 750 | 865 | 254 | 1510 | 44 | 41.3 | 1.1/2″ UNC | 1422.4 |

| Standard | |

| Design And Manufacturing | API 609 category A / IS : 13095 / BS EN 593 |

| Valve Face To Face Dimension | Short Wafer As Per ISO 5752 TAB 5 / API 609 Category A /ISO 5752 TAB 1 (BS 5155) |

| Flange Standard Conformity | Short Wafer As Per ISO 5752 TAB 5 / API 609 Category A /ISO 5752 TAB 1 (BS 5155) |

| Inspection & Testing | API 598 / BS EN 12266-1 |

| Top Flange Driling | ISO 5211 |

| TEST PRESSURE | ||

| TESTING | BODY | SEAT |

| HYDRAULIC | 16 kG/CM2 | 10 kG/CM2 |

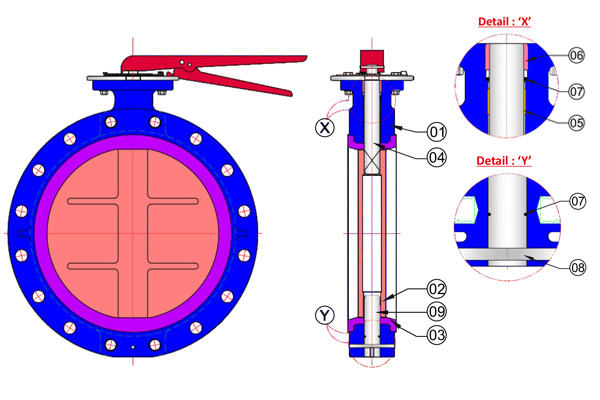

| No. | Description | Material | Qty. |

| 1 | Body | ASTM – A 126 Grade B ( Gray Iron ) | 1 |

| ASTM – A 216 Grade WCB ( Cast Steel ) | |||

| ASTM – A 536 Grade 65-45-12 ( Ductile Iron ) | |||

| ASTM – A 351 Grade CF8 / CF8M / CF3M / CD4MCuN | |||

| 2 | Disc | ASTM – A 126 Grade B ( Gray Iron ) + Powder Coated | 1 |

| ASTM – A 216 Grade WCB ( Cast Steel ) + Powder Coated | |||

| ASTM – A 536 Grade 65-45-12 ( Ductile Iron ) + Powder Coated | |||

| ASTM – A 351 Grade CF8 / CF8M / CF3M / CD4MCuN | |||

| S.G. Iron with Powder / Nylon Coated & Rubber Line | |||

| 3 | Seat | Nitrile / EPDM / Viton / Hypelon / Silicon / Neopren | 1 |

| 4 | Shaft | AISI 410 / AISI 304 / AISI 316 / AISI 316L | 1 |

| 5 | Bearing Bush | Metal Bush PTFE Coated | 2 |

| 6 | Bush | PTFE | 1 |

| 7 | ‘O’ – Ring | Nitrile / EPDM / Viton / Hypelon / Silicon / Neopren | 2 |

| 8 | Dowel Pin | M.S. / AISI 410 / AISI 304 / AISI 316 / AISI 316L | 1 |

| 9 | Bottom Pin | AISI 410 / AISI 304 / AISI 316 / AISI 316L | 1 |

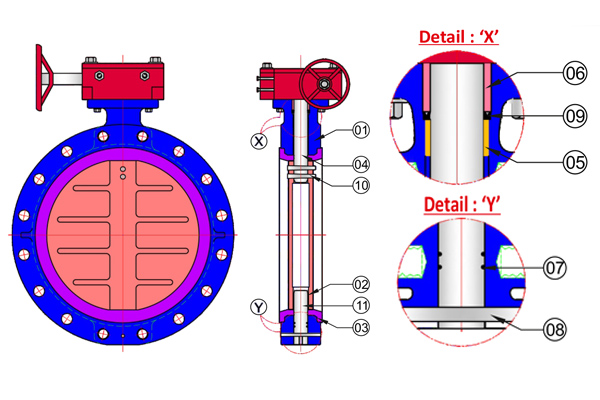

| No. | Description | Material | Qty. |

| 1 | Body | ASTM – A 126 Grade B ( Gray Iron ) | 1 |

| ASTM – A 216 Grade WCB ( Cast Steel ) | |||

| ASTM – A 536 Grade 65-45-12 ( Ductile Iron ) | |||

| ASTM – A 351 Grade CF8 / CF8M / CF3M / CD4MCuN | |||

| 2 | Disc | ASTM – A 126 Grade B ( Gray Iron ) + Powder Coated | 1 |

| ASTM – A 216 Grade WCB ( Cast Steel ) + Powder Coated | |||

| ASTM – A 536 Grade 65-45-12 ( Ductile Iron ) + Powder Coated | |||

| ASTM – A 351 Grade CF8 / CF8M / CF3M / CD4MCuN | |||

| S.G. Iron with Powder / Nylon Coated & Rubber Line | |||

| 3 | Seat | Nitrile / EPDM / Viton / Hypelon / Silicon / Neopren | 1 |

| 4 | Shaft | AISI 410 / AISI 304 / AISI 316 / AISI 316L | 1 |

| 5 | Bearing Bush | Metal Bush PTFE Coated | 2 |

| 6 | Bush | PTFE | 1 |

| 7 | ‘O’ – Ring | Nitrile / EPDM / Viton / Hypelon / Silicon / Neopren | 2 |

| 8 | Dowel Pin | MS / AISI 410 / 304 / 316 / 316L | 1 |

| 9 | ‘V’ Seal | Nitrile / EPDM / Viton / Hypelon / Silicon / Neopren | 1 |

| 10 | Taper Pin | AISI 410 / AISI 304 / AISI 316 / AISI 316L | 2 |

| 11 | Bottom Pin | AISI 304 / AISI 316 / AISI 316L | 1 |