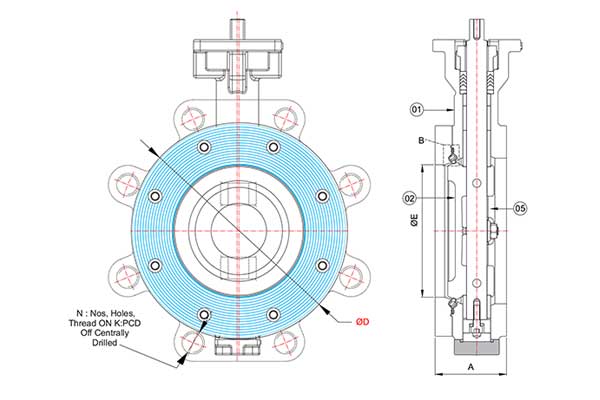

4MHP Series High Performance Butterfly Valves Dimensions 150#

4MHP MODEL Butterfly Valve Details |

|

| Pressure Rating | 150# |

| Leakage Class | Class VI (Six) |

| Seat Leakage | Tight Shut Off |

| Working Pressure | 10 Kg/cm² |

| Max Operating Temp | Up to 180°C |

| End Connection | Wafer / Lug |

| Standards | |

| Design And Manufacturing | BS EN 593 / API 609 |

| Valve Face To Face Dim | BS EN 558 / API 609 |

| Flange Standard Conformity | ASME B. 16.5 150# |

| Inspection & Testing | BS EN 12266-1/API 598 |

| Testing Detail | |

| Shell Test | 15 Kg / cm² |

| Seat Test (Hydro) | 10 Kg / cm² |

| Pneumatic | 07 Kg / cm² |

| All Dimensions are in MM | |||||||||

| Valve Size | Wafer Type | Lug Type | |||||||

| Tolerance | ±3.3 | ±3 | ±3 | ±1.5 | |||||

| MM | Inch. | A | 0D | 0E | Weight | PCD | N | Thread | Weight |

| 40 | 1.1/2″ | 42 | 82 | 38 | 1.6 kg | NA | NA | NA | NA |

| 50 | 2″ | 45 | 95 | 51 | 2.2 kg | NA | NA | NA | NA |

| 65 | 2.1/2″ | 48 | 108 | 60 | 3 kg | 139.7 | 4 | 5/8,11 | 8.16 kg |

| 80 | 3″ | 48 | 127 | 72 | 3.80 kg | 152.4 | 4 | 5/8″-11 | 8.61 kg |

| 100 | 4″ | 54 | 159 | 100 | 5.6 kg | 190.5 | 8 | 5/8″-11 | 12.7 kg |

| 125 | 5″ | 57 | 186 | 123 | 7.7 kg | 215.9 | 8 | 3/4″-10 | 17.69 kg |

| 150 | 6″ | 57 | 217 | 143 | 10.4 kg | 241.3 | 8 | 3/4″-10 | 19.95 kg |

| 200 | 8″ | 64 | 270 | 189 | 15.0 kg | 298.4 | 8 | 3/4″-10 | 30.39 kg |

| 250 | 10″ | 72 | 322 | 239 | 25.75 kg | 361.9 | 12 | 7/8″- 9 | 48.08 kg |

| 300 | 12″ | 81 | 382 | 290 | 36.00 kg | 431.8 | 12 | 70- 9 | 73.93 kg |

| 350 | 14″ | 92 | 436 | 335 | 46.90 kg | 476.3 | 12 | 1″- 8 | 118.84 kg |

| 400 | 16″ | 102 | 495 | 387.5 | 66.85 kg | 539.8 | 16 | 1″- 8 | 171.45 kg |

| 450 | 18″ | 114 | 540 | 425 | 117 kg | 577.9 | 16 | 1 1/8″ -8 | 216 kg |

| 500 | 20″ | 127 | 595 | 475 | 146.5 kg | 635 | 20 | 1 1/8″ -8 | 342.91 kg |

| 600 | 24″ | 154 | 705 | 560 | 290 kg | 749.3 | 20 | 1 1/4″ -8 | 536.59 kg |

| 750 | 30″ | 190 | 855 | 696 | 475 kg | 914.4 | 28 | 1 1/4, -8 | 767 kg |

| 900 | 36″ | 203 | 1032 | 864 | 675 kg | 1085.8 | 32 | 1 1/2″ -8 | 1090.88 kg |

| No. | Description | Material |

| 1 | Body | ASTM A 216 Gr. WCB |

| ASTM A351 Gr. CF8 | ||

| ASTM A351 Gr. CF8M | ||

| 2 | Disc | ASTM A351 Gr. CF8 |

| ASTM A351 Gr. CF8M | ||

| 3 | Seat | RPTFE |

| 4 | O-Ring | VITON |

| 5 | Shaft | ASTM A276 TYPE S.S. 410 |

| ASTM A 564 GR.17 – 4 PH | ||

| ASTM A276 TYPE S.S. 304 | ||

| ASTM A276 TYPE S.S. 316 |

| CV VALUES | ||||||||||

| Valve Size | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| MM | Inch | |||||||||

| 50 | 2” | 2 | 5 | 11 | 19 | 28 | 41 | 58 | 77 | 85 |

| 65 | 2.1/2” | 2 | 9 | 20 | 28 | 45 | 60 | 80 | 120 | 130 |

| 80 | 3” | 3 | 10 | 22 | 42 | 64 | 95 | 150 | 157 | 150 |

| 100 | 4” | 6 | 17 | 41 | 75 | 116 | 174 | 273 | 284 | 290 |

| 125 | 5” | 6 | 45 | 75 | 170 | 280 | 478 | 650 | 707 | 795 |

| 150 | 6” | 7 | 51 | 116 | 221 | 340 | 510 | 799 | 833 | 850 |

| 200 | 8” | 4 | 103 | 239 | 445 | 684 | 1026 | 1607 | 1676 | 1710 |

| 250 | 10” | 50 | 151 | 353 | 655 | 1008 | 1515 | 2369 | 2470 | 2520 |

| 300 | 12” | 79 | 236 | 552 | 1024 | 1576 | 2364 | 3704 | 3861 | 3940 |

| VALVE TORQUE 150# | ||||

| Valve Size | 5 Bar | 10 Bar | 20 Bar | |

| MM | Inch | Nm | Nm | Nm |

| 50 | 2” | 11 | 15 | 21 |

| 65 | 2.1/2” | 20 | 28 | 38 |

| 80 | 3” | 38 | 43 | 63 |

| 100 | 4” | 50 | 58 | 80 |

| 125 | 5” | 73 | 100 | 144 |

| 150 | 6” | 113 | 144 | 181 |

| 200 | 8” | 175 | 219 | 350 |

| 250 | 10” | 294 | 331 | 375 |

| 300 | 12” | 400 | 450 | 625 |

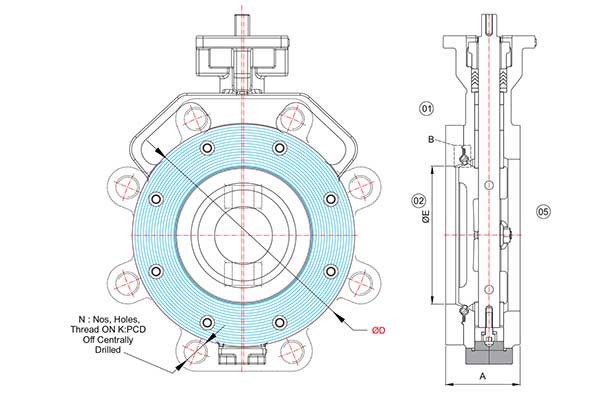

4MHP Series High Performance Butterfly Valves Dimensions 300#

| 4MHP MODEL Butterfly Valve Details | |

| Pressure Rating | 300# |

| Leakage Class | Class VI (Six) |

| Seat Leakage | Tight Shut Off |

| Working Pressure | 20 Kg/cm² |

| Max Operating Temp | Up to 180°C |

| End Connection | Wafer / Lug |

| Standards | |

| Design And Manufacturing | BS EN 593 / API 609 |

| Valve Face To Face Dim | BS EN 558 / API 609 |

| Flange Standard Conformity | ASME B. 16.5 300# |

| Inspection & Testing | BS EN 12266-1/API 598 |

| Testing Detail | |

| Shell Test | 30 Kg / cm² |

| Seat Test (Hydro) | 20 Kg / cm² |

| Pneumatic | 07 Kg / cm² |

| Valve Size | Wafer Type | Lug Type | |||||||

| Tolerance | ±3.3 | ±3 | ±3 | ±1.5 | |||||

| MM | Inch. | A | OD | OE | Weight | PCD | N | Thread | Weight |

| 65 | 2.1/2″ | 48 | 108.5 | 60.0 | 5.4 kg | 149.2 | 8 | 3/4″-10 | 8.16 kg |

| 80 | 3″ | 48 | 127 | 72 | 6.84 kg | 168.3 | 8 | 3/4″-10 | 8.61 kg |

| 100 | 4″ | 54 | 159 | 100 | 10.08 kg | 200 | 8 | 3/4″-10 | 12.7 kg |

| 125 | 5″ | 59 | 187 | 123 | 13.86 kg | 235 | 8 | 3/4″-10 | 17.69 kg |

| 150 | 6″ | 59 | 219 | 143.2 | 18.72 kg | 269.9 | 12 | 3/4″-10 | 27.66 kg |

| 200 | 8″ | 64 | 270 | 192 | 27 kg | 330.2 | 12 | 7/8″- 9 | 46.72 kg |

| 250 | 10″ | 87 | 340 | 239.2 | 46.35 kg | 387.4 | 16 | 1 “- 8 | 73.48 kg |

| 300 | 12″ | 92 | 394 | 290 | 64.8 kg | 450.8 | 16 | 1-1/8″- 8 | 112.49 kg |

| 350 | 14″ | 117 | 436 | 335 | 84.42 kg | 514.4 | 20 | 1-1/8″- 8 | 185.97 kg |

| 400 | 16″ | 113 | 500 | 387.5 | 120.33 kg | 571.5 | 20 | 1-1/4″- 8 | 305.26 kg |

| 450 | 18″ | 149 | 540 | 425 | 210.6 kg | 628.6 | 24 | 1-1/4″- 8 | 370.13 kg |

| 500 | 20″ | 159 | 595 | 475 | 263.7 kg | 685.8 | 24 | 1-1/4″- 8 | 466.29kg |

| 600 | 24″ | 181 | 705 | 560 | 522 kg | 812.8 | 24 | 1-1/2″- 8 | 834.15 kg |

| No. | Description | Material |

| 1 | Body | ASTM A 216 Gr. WCB |

| ASTM A351 Gr. CF8 | ||

| ASTM A351 Gr. CF8M | ||

| 2 | Disc | ASTM A351 Gr. CF8 |

| ASTM A351 Gr. CF8M | ||

| 3 | Seat | RPTFE |

| 4 | O-Ring | VITON |

| 5 | Shaft | ASTM A276 TYPE S.S. 410 |

| ASTM A 564 GR.17 – 4 PH | ||

| ASTM A276 TYPE S.S. 304 | ||

| ASTM A276 TYPE S.S. 316 |

| CV VALUES | ||||||||||

| Valve Size | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| MM | Inch | |||||||||

| 80 | 3” | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – |

| 100 | 4” | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – |

| 125 | 5” | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – | – – – |

| 150 | 6” | 17.4 | 61 | 120 | 190 | 290 | 420 | 680 | 770 | 870 |

| 200 | 8” | 27.2 | 100 | 200 | 300 | 460 | 640 | 1070 | 1200 | 1370 |

| 250 | 10” | 42 | 150 | 290 | 460 | 690 | 980 | 1630 | 1840 | 2090 |

| 300 | 14” | 73 | 260 | 510 | 800 | 1200 | 1710 | 2840 | 3200 | 3640 |

| 400 | 16” | 100 | 350 | 700 | 1100 | 1660 | 2360 | 3914 | 4410 | 5010 |

| 450 | 18” | 120 | 440 | 870 | 1360 | 2040 | 2900 | 4810 | 5430 | 6170 |

| 500 | 20” | 170 | 580 | 1160 | 1810 | 2720 | 3870 | 6400 | 7250 | 8250 |

| 600 | 24” | 260 | 900 | 1800 | 2830 | 4250 | 6050 | 10000 | 11300 | 12900 |

| VALVE TORQUE 300# | |||||||

| Valve Size | 10 Bar | 20 Bar | 25 Bar | 35 Bar | 40 Bar | 50 Bar | |

| MM | Inch | Nm | Nm | Nm | Nm | Nm | Nm |

| 80 | 3” | 55 | 62 | 70 | 75 | 76 | 80 |

| 100 | 4” | 72 | 89 | 104 | 111 | 114 | 125 |

| 125 | 5” | 96 | 127 | 137 | 148 | 160 | 178 |

| 150 | 6” | 126 | 138 | 178 | 194 | 205 | 220 |

| 200 | 8” | 205 | 252 | 281 | 304 | 328 | 354 |

| 250 | 10” | 325 | 468 | 503 | 560 | 594 | 663 |

| 300 | 12” | 465 | 685 | 777 | 868 | 937 | 1005 |

| 350 | 14” | 747 | 1126 | 1461 | 1776 | 1836 | 2021 |

| 400 | 16” | 1065 | 1654 | 2020 | 2204 | 2448 | 2700 |

| 450 | 18” | 1346 | 2143 | 2458 | 2938 | 3183 | 3428 |

| 500 | 20” | 2014 | 3056 | 3590 | 3852 | 4244 | 4570 |

| 600 | 24” | 3052 | 4578 | 5223 | 5876 | 6464 | 6971 |

4MHP Series available with Electric Actuator

- Various power supply:

Single Phase – 220V AC 50/60 Hz, 110V AC, 48V DC, 24V DC, 12V DC Three Phase – 415V AC 50/60 Hz, 380V AC, 460V AC

- Enclosure :

IP 67/68, Weather-proof (IS / IEC 60529),

Flame-proof or Ex-proof (IS/IEC 60079) Zone II, Gas Group IIB T4

- Manual Override:

Scada / PCL compatiable Advanced design with auto declutch mechanism to prevent user from injury.

- Integral Starter Unit:

Selector Switches : Open/ Stop/Close Auto/ Manual or Remote / Local

- Indicator Lamps :

Open/ Close / Error

- Characteristics: On / Off type :

Modulation Control (Signal Input: 4~20mA /1~5V DC / 2~10V DC) Potentiometer Feedback (4~20mA)

Auxiliary Limit Switches (2 Units) 2 wire for On/Off operation

4MHP Series available with Pneumatic Actuator

- Various Pneumatic Actuators:

- Scotch & Yoke Actuator

- Pneumatic Rotary Actuator 3 Position Pneumatic Rotary Actuator Stainless Steel Pneumatic Rotary Actuator Single Acting Pneumatic Rotary Actuator Double Acting

- Aluminium Body Scotch Yoke Pneumatic Actuator Pneumatic Single Acting Double Decker Actuator

- Accessories

- Pneumatic – Pneumatic Valve Positioner Electro – Pneumatic Valve Positioner Smart Positioner

- Euro Switch

- Weather Proof Micro Limit Switch Box Flam Proof Limit Switch Box

- Flame Proof Stainless Steel Micro Limit Switch Box

- 3/2 way and 5/2 way Namur Solenoid Valve (All standard voltage available) Poppet type Namur Solenoid Valve

- Spool type Namur Solenoid Valve Filter Regulator

- Air Volume Booster Air Lock Valve