PTFE ( FEP/PFA) Lined Ball Valve

India’s Leading Lined Ball Valve Manufacturer & Supplier

“4Matic” Offers Pneumatic Actuator Operated Lined Ball Valves offers economical solution for the vast majority of chemical applications while maintaining the highest possible degree of performance in terms of in-line leakage and fugitive emissions. The lower torque of our lined ball valve design permits use of smaller actuators, allowing cost reductions and creating space saving opportunities. The dynamic body joint design retains pressure boundary during thermal cycles.

Size Range : : 1/2″ to 8″ Flanged

| Valve Specification | |

| Working Pressure | 10 Kg/cm2 |

| Working Temperature | FEP : Upto 180 °C PFA : Upto 230 °C |

| Valve Rating | 150# |

| Standard | |

| Design And Manufacturer | ASME B 16.34 / BS EN ISO 17292 |

| Valve Face To Face Dimension | As Per Manufacturer std. |

| Flange Standard Conformity | ASME B 16.5 Class 150 / 300 |

| Inspection & Testing | Class VI ISO – 5208 |

| Leakage Class | Class VI ISO – 5208 |

- On / OFF Indicator

- NAMUR Standard Solenoid Valve in all Standard Coil Voltage (Flame Proof Solenoid Coil – On Request)

- Pneumatic & Electro-Pneumatic valve positioner

- Declutchable Manual Over – Ride

- Limit Switches for On / Off Indication at Panel Board

- Filter + Regulator Combination with Pressure Gauge

- Air Lock Valve

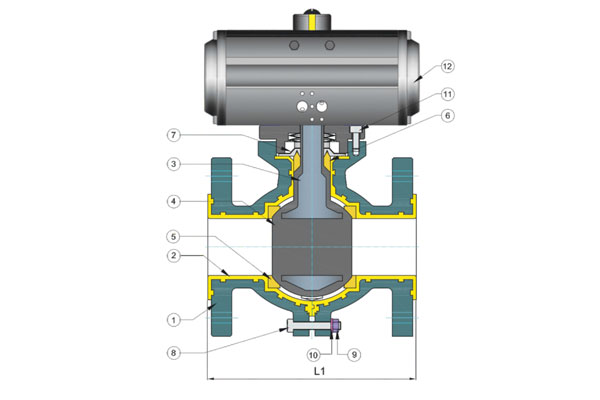

Dimensions :

| Valve Model | Valve Size | L1 | Weight Approx. | ||

| Inch | MM | S. G. Iron | IC CF8 | ||

| 4M-TBA – 15 | ½” | 15 | 140 | —- | 4.000 |

| 4M-TBA – 20 | ¾” | 20 | 140 | —- | 4.670 |

| 4M-TBA – 25 | 1” | 25 | 130.5 | 7.700 | 7.400 |

| 4M-TBA – 40 | 1.1/2” | 40 | 167 | 10.100 | 9.700 |

| 4M-TBA – 50 | 2” | 50 | 181 | 14.700 | 12.900 |

| 4M-TBA – 65 | 2.1/2” | 65 | 206 | 22.100 | 19.200 |

| 4M-TBA – 80 | 3” | 80 | 207 | 30.500 | 30.900 |

| 4M-TBA – 100 | 4” | 100 | 226 | 39.500 | 37.500 |

| 4M-TBA – 150 | 6” | 150 | 267 | On Req. | On Req. |

| 4M-TBA – 200 | 8 | 200 | 465 | On Req. | On Req. |

(All Dimensions are in mm)

| Sr. No. | Description | Material |

| 1 | Body | WCB/CF8/CF8M/S. G. Iron/ D. I. |

| 2 | Body Molding | FEP/PFA |

| 3 | Ball with Shaft | CF8/CF8M |

| 4 | Ball Molding | FEP/PFA |

| 5 | Ball Seat | PTFE/GFT/CFT/TFM |

| 6 | Shaft Bush | PTFE/GFT/CFT/TFM |

| 7 | Packing Water | Spring Steel |

| 8 | Bolt | S. S. 304 |

| 9 | Nut | S. S. 304 |

| 10 | Washer | S. S. 304 |

| 11 | L. N. Bolt | S. S. 304 |

| 12 | Actuator | STD. |

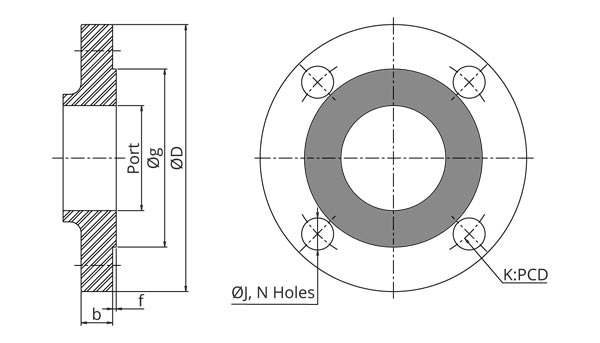

For Ball Valves Flange Standards Dimension Table :

| As Per ASME B16.5 150# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 108 | 90 | 34.9 | 9.6 | 2 | 15.9 | 4 | 60.3 |

| 3/4″ | 20 | 19 | 117 | 100 | 42.9 | 11.2 | 2 | 15.9 | 4 | 69.9 |

| 1″ | 25 | 25 | 127 | 110 | 50.8 | 12.7 | 2 | 15.9 | 4 | 79.4 |

| 1.1/4″ | 32 | 32 | 140 | 115 | 63.5 | 14.3 | 2 | 15.9 | 4 | 88.9 |

| 1.1/2″ | 40 | 38 | 165 | 125 | 73 | 15.9 | 2 | 15.9 | 4 | 98.4 |

| 2″ | 50 | 49 | 178 | 150 | 92.1 | 17.5 | 2 | 19.05 | 4 | 120.7 |

| 2.1/2″ | 65 | 62 | 190 | 180 | 104.8 | 20.7 | 2 | 19.05 | 4 | 139.7 |

| 3″ | 80 | 74 | 203 | 190 | 127 | 22.3 | 2 | 19.05 | 4 | 152.4 |

| 4″ | 100 | 100 | 229 | 230 | 157.2 | 22.3 | 2 | 19.05 | 8 | 190.5 |

| 5″ | 125 | 125 | 254 | 255 | 185.7 | 22.3 | 2 | 22.2 | 8 | 215.9 |

| 6″ | 150 | 150 | 267 | 280 | 215.9 | 23.9 | 2 | 22.2 | 8 | 241.3 |

| 8″ | 200 | 201 | 292 | 345 | 269.9 | 27 | 2 | 22.2 | 8 | 298.5 |

| 10″ | 250 | 252 | 330 | 405 | 323.8 | 28.6 | 2 | 25.4 | 12 | 362 |

| 12″ | 300 | 303 | 610 | 485 | 381 | 30.2 | 2 | 25.4 | 12 | 431.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 300# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 140 | 95 | 34.9 | 12.7 | 2 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 152 | 115 | 42.9 | 14.3 | 2 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 165 | 125 | 50.8 | 15.9 | 2 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 178 | 135 | 63.5 | 17.5 | 2 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 190 | 155 | 73 | 19.1 | 2 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 216 | 165 | 92.1 | 20.7 | 2 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 241 | 190 | 104.8 | 23.9 | 2 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 282 | 210 | 127 | 27 | 2 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 305 | 255 | 157.2 | 30.2 | 2 | 22.2 | 8 | 200 |

| 5″ | 125 | 125 | 381 | 280 | 185.7 | 33.4 | 2 | 22.2 | 8 | 235 |

| 6″ | 150 | 150 | 403 | 320 | 215.9 | 35 | 2 | 22.2 | 12 | 269.9 |

| 8″ | 200 | 201 | 419 | 380 | 269.9 | 39.7 | 2 | 25.4 | 12 | 330.2 |

| 10″ | 250 | 252 | 457 | 445 | 323.8 | 46.1 | 2 | 28.6 | 16 | 387.4 |

| 12″ | 300 | 303 | 648 | 520 | 381 | 49.3 | 2 | 31.75 | 16 | 450.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 600# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 165 | 95 | 34.9 | 14.3 | 7 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 190 | 115 | 42.9 | 15.9 | 7 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 216 | 125 | 50.8 | 17.5 | 7 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 229 | 135 | 63.5 | 20.7 | 7 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 241 | 155 | 73 | 22.3 | 7 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 292 | 165 | 92.1 | 25.4 | 7 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 330 | 190 | 104.8 | 28.6 | 7 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 356 | 210 | 127 | 31.8 | 7 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 432 | 275 | 157.2 | 38.1 | 7 | 25.4 | 8 | 215.9 |

| 5″ | 125 | 125 | 508 | 330 | 185.7 | 44.5 | 7 | 28.6 | 8 | 266.7 |

| 6″ | 150 | 150 | 559 | 355 | 215.9 | 47.7 | 7 | 28.6 | 12 | 292.1 |

| 8″ | 200 | 201 | 660 | 420 | 269.9 | 55.6 | 7 | 31.75 | 12 | 349.2 |

| 10″ | 250 | 252 | 787 | 510 | 323.8 | 63.5 | 7 | 34.9 | 16 | 431.8 |

| 12″ | 300 | 303 | 838 | 560 | 381 | 66.7 | 7 | 34.9 | 20 | 489 |

(All Dimensions are in mm)

Note : 900# / 1500# / 2500# Available On Request.

Actuator Ball valve in India

Actuator Ball Valve in India is an efficient and reliable as well as safe sources of motion control that use compressed pressurized air to convert energy into linear or rotary motion. They are especially useful for the continuous opening-closing of mechanical valves and other industrial equipment applications where the use of electricity may cause fire and ignition hazards. Actuators are used to control the Mechanical valves that direct the movements of fluids in various chemical and process industries globally. As these are simple in construction, have less maintenance and low cost-effective in valves automation industries.