Pilot Operated Pressure Reducing Valve

Technical Specification

Model: 4M STM

Screwed End : 15MM to 50MM (BSP / NPT)

Flanged End : 15MM to 80MM (150# / 300# / DIN / IS1538 / JIS )

Body: CI / DI / WCB / CF8 / CF8M

Pressure Rating : PN10 / PN16 / PN25 / PN40

Seat: Metal to Metal

Temperature: Upto 350° C

Pressure Range: 0.5 to 10 BAR – 10 to 20 BAR

Working Principle

This kind of PRV blends two valves in a single unit, i.e., a Pilot as well as a main valve. The pilot valve has the same design as that of the direct-acting valve. The flow out from the pilot valve works on a set of double diaphragms that are regulated by a piston of the opening of the principal valve. This high diaphragm zone can open a bigger main valve, permitting a larger volume per line size as compared to the direct-acting controllers. Furthermore, the diaphragms are more susceptible to pressure alterations which mean accuracy to the tune of +/- 1%. Because of the position of the sensing line outside the valve, where the turbulence is lesser, becomes the reason for this significant precision. This valve also provides the flexibility for the utilization of various kinds of pilot valves, such as pressure, temperature, air loaded, solenoid or combinations thereof.

As it is a steam, pressure reducing valve it functions as an automatic control valve which is utilized to reduce uncontrolled high level inlet pressure to a reduced and consistent outlet pressure regardless of variations in upstream steam pressure. A steam pressure reducing valve is made use of in various steam applications so as to regulate the flow of steam. Important for giving the right level of steam pressure in plants, this valve, due to its crucial role, proves very supportive. Steam enters in the steam pressure-reducing valve at a high level of pressure as compared to the required at downstream. The valve assists in reducing the pressure as per the needed level before it is supplied to the required place. In general, steam pressure reducing valves are utilized in industrial, commercial as well as institutional applications for regulating steam pressure. The span of its usage includes oil lines, testing fixtures, single radiators, autoclaves, vulcanizers, steam irons, etc. Steam pressure reducing valve is an automatic valve, which assures to control the excessive pressure in a system. This valve is also called a steam pressure-reducing regulator.

Operation

The principal valve is closed and the pilot valve opens through spring air pressure or spring force – this is the usual position prior to start- up. Steam moves through the pilot valve to the diaphragm chamber and gets out through the control orifice. At the time, when the flow through the pilot valve becomes greater than the flow through the orifice, the diaphragm control pressure rises and the principal (main) valve gets open. When the steam flows through the principal (main) valve, the downstream pressure rises and by the pressure sensing line it feeds back to the lower side of the pressure diaphragm. The pilot valve starts to throttle as soon as the compression force and the force below the diaphragm is balanced. The main diaphragm control pressure maintained makes the main or principal valve to let free necessary steam required for delivery pressure. Any adjustment in the air pressure or spring above the diaphragm results into change in the downstream pressure. When there is no need of steam, the sensing line pressure is raised, that shuts the pressure pilot while control pressure moves back through control orifice. This assists the main or principal valve for holding required pressure and it can close tight to increase dead-end shutoff.

Characteristics

- Steam pressure reducing valves do not require an outer source of

- Steam pressure reducing valves are more cost effective due to the adaptation of uncomplicated

- Steam pressure reducing valves provide quick

- Feedback controllers or separate components for measurement are not required for these

- Steam pressure reducing valves have proven most consistent performance as well as cost effective maintenance.

- As these valves have no stem packing, it results into elimination of external leakage and high

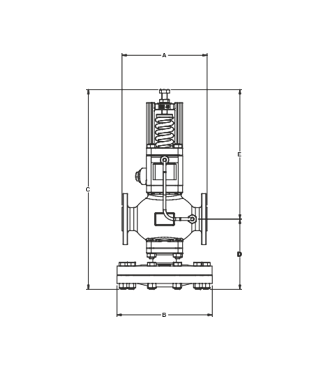

DIMENSIONS: Flanged End

| Size (DN) | A | B | C | D | E | Weight |

| 15 | 147 | 175 | 400 | 130 | 270 | 15 |

| 20 | 167 | 175 | 410 | 130 | 280 | 17 |

| 25 | 184 | 206 | 415 | 146 | 271 | 23 |

| 32 | 184 | 206 | 425 | 146 | 280 | 25 |

| 40 | 253 | 280 | 490 | 185 | 305 | 40 |

| 50 | 253 | 280 | 490 | 185 | 305 | 42 |

| 80 | 328 | 350 | 598 | 266 | 331 | 103 |

| (Note : Dimensions (approx.) mm and kg) | ||||||

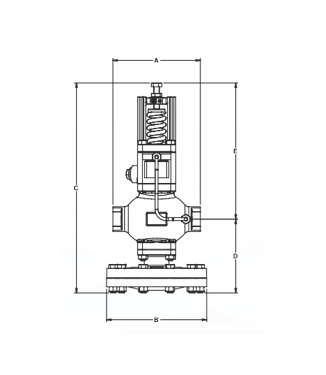

DIMENSIONS: Screwed End

| Size (DN) | A | B | C | D | E | Weight |

| 15 | 147 | 175 | 400 | 130 | 270 | 14 |

| 20 | 167 | 175 | 410 | 130 | 280 | 15 |

| 25 | 184 | 206 | 415 | 146 | 271 | 21 |

| 32 | 184 | 206 | 425 | 146 | 280 | 22 |

| 40 | 253 | 280 | 490 | 185 | 305 | 36 |

| 50 | 253 | 280 | 490 | 185 | 305 | 38 |

| (Note : Dimensions (approx.) mm) | ||||||

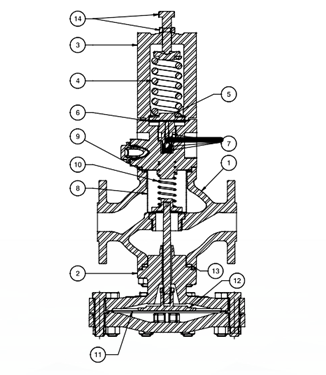

| Sr. No. | Description | Material |

| 1 | Body | CI / DI / WCB / CF8 / CF8M |

| 2 | Chamber | CI / DI / WCB / CF8 / CF8M |

| 3 | Spring Housing Cover | CI / DI / WCB / CF8 / CF8M |

| 4 | Pressure Adjutment Spring | Spring Steel |

| 5 | Bottom Spring Plate | S.S. 304 / S.S. 316 |

| 6 | Pilot Diaphragm | S.S. 304 / S.S. 316 |

| 7 | Pilot Valve with Internal Parts | S.S. 304 / S.S. 316 |

| 8 | Internal Strainer | S.S. 304 / S.S. 316 |

| 9 | Gasket for Body | Reinforced Exfoliate Graphite |

| 10 | Return Spring | Spring Steel |

| 11 | Main Diaphragm | S.S. 304 / S.S. 316 |

| 12 | Main Diaphragm Plate | S.S. 304 / S.S. 316 |

| 13 | Gasket for Chamber | Reinforced Exfoliated Graphite |

| 14 | Adjustment Screw and Nut | Carbon Steel |

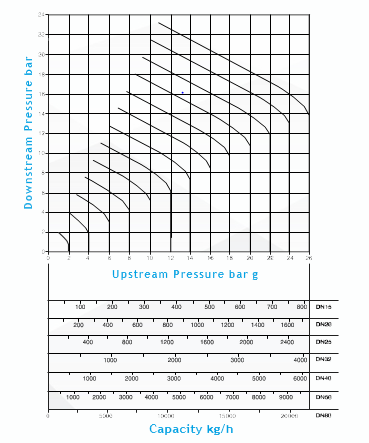

Steam Capacity Chart