API 6D Trunnion Mounted Ball Valve

“4Matic” Offers Pneumatic Actuator Operated, The Inconel Spring Trunnion Mounted Ball Valve is a robust API 6D monogrammed 2 piece design with bi-directional sealing. SRE Series trunnion mounted ball valves are designed for general industrial and chemical applications, and include the following features standard. chemical, oil, petrochemical, gas, pulp, paper processing and other industries. Chemical, Pharmaceutical, Food, Pharmaceutical, Petrochemical, Energy, Plastics, Oil & Gas, Cement & lubrication

Size Range : : 4″ to 24″ Flanged

DBB (Single Piston Design)

DIB – 1 : Double isolation and bleed valve (Double Piston Design On Request)

DIB – 2 : Double isolation and bleed valve

One side Single piston(uni-directional),one side double piston(bi-directional)

| Standard | |

| Design And Manufacturer | API 6D |

| Valve Face To Face Dimension | API 6D |

| Flange Standard Conformity | ASME B 16.5 150# & 300# |

| Inspection & Testing | API – 6D |

Accessories

- On / OFF Indicator

- NAMUR Standard Solenoid Valve in all Standard Coil Voltage (Flame Proof Solenoid Coil – On Request)

- Pneumatic & Electro-Pneumatic valve positioner

- Declutchable Manual Over – Ride

- Limit Switches for On / Off Indication at Panel Board

- Filter + Regulator Combination with Pressure Gauge

- Air Lock Valve

Dimensions :

| Valve Model | Valve Size | Flanged 150# | Flanged 300# | |

| Inch | MM | L1 | L1 | |

| 4M-SRE-100 | 4″ | 100 | 228 | 305 |

| 4M-SRE-125 | 5″ | 125 | 394 | 403 |

| 4M-SRE-150 | 6″ | 150 | 394 | 403 |

| 4M-SRE-200 | 8″ | 200 | 457 | 502 |

| 4M-SRE-250 | 10″ | 250 | 533 | 568 |

| 4M-SRE-300 | 12″ | 300 | 610 | 648 |

| 4M-SRE-350 | 14″ | 350 | 686 | 782 |

| 4M-SRE-400 | 16″ | 400 | 762 | 838 |

| 4M-SRE-450 | 18″ | 450 | 864 | 914 |

| 4M-SRE-500 | 20″ | 500 | 914 | 991 |

| 4M-SRE-600 | 24″ | 600 | 1067 | 1143 |

(All Dimensions are in mm)

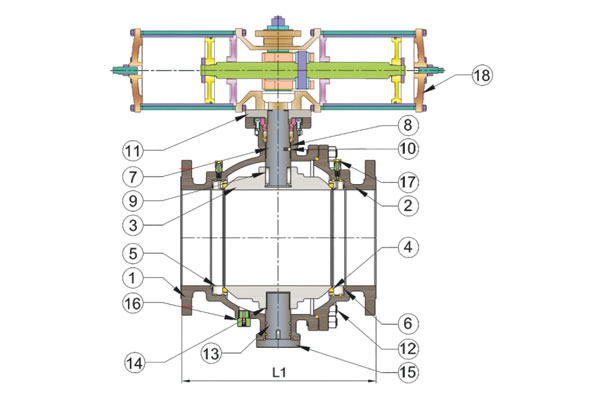

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M / CF3M |

| 2 | Connector | WCB / CF8 / CF8M / CF3M |

| 3 | Ball | CF8 / CF8M / CF3M |

| 4 | Ball Seat | PTFE |

| 5 | Adapter | CF8 / CF8M |

| 6 | Spring | Inconel |

| 7 | Stem Pin | S.S.304 \S.S. 316 |

| 8 | Distance Bush For Stem | S.S.304 |

| 9 | Key For Shaft | S.S.304 |

| 10 | Spring & Ball For Anti Static | S.S.304 |

| 11 | Acuator Plate | S.S.304 |

| 12 | Body Fitting Stud + Hex Nut | M.S / S.S.304 |

| 13 | Trunnion Pin | S.S.304 / S.S.316 |

| 14 | Distance Bush For Trunnion | S.S.304 |

| 15 | Trunnion Plate | S.S.304 |

| 16 | Drain & Vent | S.S.304 |

| 17 | Sealent | S.S.304 |

| 18 | Actuator | STD. |

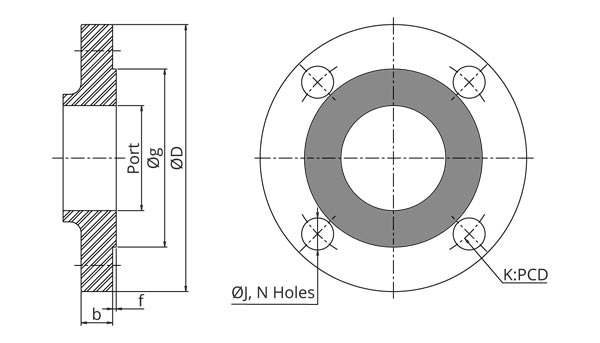

For Ball Valves Flange Standards Dimension Table :

| As Per ASME B16.5 150# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 108 | 90 | 34.9 | 9.6 | 2 | 15.9 | 4 | 60.3 |

| 3/4″ | 20 | 19 | 117 | 100 | 42.9 | 11.2 | 2 | 15.9 | 4 | 69.9 |

| 1″ | 25 | 25 | 127 | 110 | 50.8 | 12.7 | 2 | 15.9 | 4 | 79.4 |

| 1.1/4″ | 32 | 32 | 140 | 115 | 63.5 | 14.3 | 2 | 15.9 | 4 | 88.9 |

| 1.1/2″ | 40 | 38 | 165 | 125 | 73 | 15.9 | 2 | 15.9 | 4 | 98.4 |

| 2″ | 50 | 49 | 178 | 150 | 92.1 | 17.5 | 2 | 19.05 | 4 | 120.7 |

| 2.1/2″ | 65 | 62 | 190 | 180 | 104.8 | 20.7 | 2 | 19.05 | 4 | 139.7 |

| 3″ | 80 | 74 | 203 | 190 | 127 | 22.3 | 2 | 19.05 | 4 | 152.4 |

| 4″ | 100 | 100 | 229 | 230 | 157.2 | 22.3 | 2 | 19.05 | 8 | 190.5 |

| 5″ | 125 | 125 | 254 | 255 | 185.7 | 22.3 | 2 | 22.2 | 8 | 215.9 |

| 6″ | 150 | 150 | 267 | 280 | 215.9 | 23.9 | 2 | 22.2 | 8 | 241.3 |

| 8″ | 200 | 201 | 292 | 345 | 269.9 | 27 | 2 | 22.2 | 8 | 298.5 |

| 10″ | 250 | 252 | 330 | 405 | 323.8 | 28.6 | 2 | 25.4 | 12 | 362 |

| 12″ | 300 | 303 | 610 | 485 | 381 | 30.2 | 2 | 25.4 | 12 | 431.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 300# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 140 | 95 | 34.9 | 12.7 | 2 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 152 | 115 | 42.9 | 14.3 | 2 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 165 | 125 | 50.8 | 15.9 | 2 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 178 | 135 | 63.5 | 17.5 | 2 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 190 | 155 | 73 | 19.1 | 2 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 216 | 165 | 92.1 | 20.7 | 2 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 241 | 190 | 104.8 | 23.9 | 2 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 282 | 210 | 127 | 27 | 2 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 305 | 255 | 157.2 | 30.2 | 2 | 22.2 | 8 | 200 |

| 5″ | 125 | 125 | 381 | 280 | 185.7 | 33.4 | 2 | 22.2 | 8 | 235 |

| 6″ | 150 | 150 | 403 | 320 | 215.9 | 35 | 2 | 22.2 | 12 | 269.9 |

| 8″ | 200 | 201 | 419 | 380 | 269.9 | 39.7 | 2 | 25.4 | 12 | 330.2 |

| 10″ | 250 | 252 | 457 | 445 | 323.8 | 46.1 | 2 | 28.6 | 16 | 387.4 |

| 12″ | 300 | 303 | 648 | 520 | 381 | 49.3 | 2 | 31.75 | 16 | 450.8 |

(All Dimensions are in mm)

| As Per ASME B16.5 600# Dimensions Table | ||||||||||

| Valve Size | Port | L1 | ØD | Øg | b | f | ØJ | N | PCD | |

| Inch | MM | |||||||||

| 1/2″ | 15 | 13 | 165 | 95 | 34.9 | 14.3 | 7 | 15.9 | 4 | 66.7 |

| 3/4″ | 20 | 19 | 190 | 115 | 42.9 | 15.9 | 7 | 19.05 | 4 | 82.6 |

| 1″ | 25 | 25 | 216 | 125 | 50.8 | 17.5 | 7 | 19.05 | 4 | 88.9 |

| 1.1/4″ | 32 | 32 | 229 | 135 | 63.5 | 20.7 | 7 | 19.05 | 4 | 98.4 |

| 1.1/2″ | 40 | 38 | 241 | 155 | 73 | 22.3 | 7 | 22.2 | 4 | 114.3 |

| 2″ | 50 | 49 | 292 | 165 | 92.1 | 25.4 | 7 | 19.05 | 8 | 127 |

| 2.1/2″ | 65 | 62 | 330 | 190 | 104.8 | 28.6 | 7 | 22.2 | 8 | 149.2 |

| 3″ | 80 | 74 | 356 | 210 | 127 | 31.8 | 7 | 22.2 | 8 | 168.3 |

| 4″ | 100 | 100 | 432 | 275 | 157.2 | 38.1 | 7 | 25.4 | 8 | 215.9 |

| 5″ | 125 | 125 | 508 | 330 | 185.7 | 44.5 | 7 | 28.6 | 8 | 266.7 |

| 6″ | 150 | 150 | 559 | 355 | 215.9 | 47.7 | 7 | 28.6 | 12 | 292.1 |

| 8″ | 200 | 201 | 660 | 420 | 269.9 | 55.6 | 7 | 31.75 | 12 | 349.2 |

| 10″ | 250 | 252 | 787 | 510 | 323.8 | 63.5 | 7 | 34.9 | 16 | 431.8 |

| 12″ | 300 | 303 | 838 | 560 | 381 | 66.7 | 7 | 34.9 | 20 | 489 |

(All Dimensions are in mm)

Note : 900# / 1500# / 2500# Available On Request.