VALVE TORQUE & ACTUATOR SELECTION. . . . . . A SUMMARY

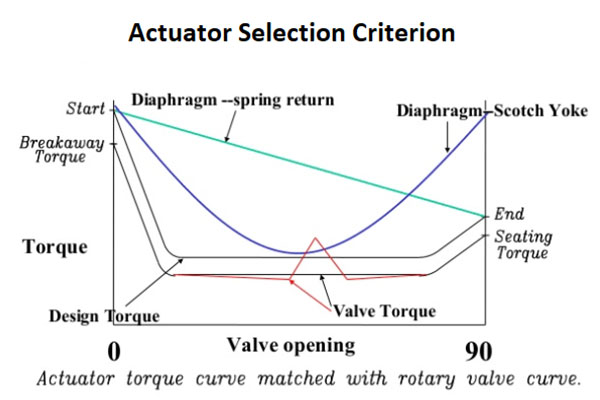

The force OR strength needed at the time of opening and closing of the valve is the Valve Torque, which is the vital criteria for selecting the correct 4Matic Actuator. Close the valve between the opening and closing parts of the seat sealing surface to make a sealed pressure, but also to get control of the stem and packing, stem and nut thread, stem end support and other friction components of the friction force, where the requirement for a particular opening force, its highest is in the eventual point of time of closure or the starting point of time of opening. The starting torque of any manual valve should not go beyond 360Nm. If it goes beyond this, proper driving actuators like, electric, pneumatic and hydraulic must be taken into consideration. The design and production of valves should be in accordance so as to have reduction in opening/closing force and torque.

The working torque popularly known as the operating torque, can be derived through calculation or measurement or by genuine measurement through tools such as a torque wrench. 4Matic Electric Actuators as well as Pneumatic Actuators are at hand for 1.5 times* the valve torque. In case, where the valve opening torque is very large, the gear or worm gear transmission can be made use of. The various types of 4Matic valves have distinct torque.

While calculating the torque of Ball valves, three types of friction are to be taken in to consideration:

-Ball and Seat friction torque,

-Friction torque of packing on the stem,

-Friction torque of the bearing on the stem.

The calculation of the torque of the Ball valve can be done as per the following formula :

The Ball valve’s total stem torque.

M=M1+M2+M3

M1: Friction torque between the Ball and sealing surface of valve seat.

M2: Friction torque between packing and stem due to medium pressure.

M3: Friction torque on top of the stem.

Furthermore, while calculating valve torque, a thorough analysis should be made with regard to the medium (media and application), material and other parts of the friction factor. This is necessary as, there are various kinds of disc, seat and packing and they all have distinct friction, contact surfaces, compression etc. The calculated valve torque varies from the real measured value and therefore, can not considered as a benchmark. The precise value requires to be rectified in coalition with the test outcome of every valve manufacturer.

Feel free to contact us for more information.