It is often observed that friction, groove and such other faults become visible on the disc and seat as well as other internal parts of control valve and reducing valve. These defects are generally happen due to cavitation. This cavitation is nothing but an entire process of bubble accumulation, movement, division and elimination. During the passing of the liquid through the partially open valve, the steady pressure is less than the saturated pressure of the liquid in the space of rising velocity or closing of the valve there after. At this point, the liquid in the low pressure area starts to evaporate and generates small bubbles which soak-up the impurities in the liquid. While the bubble is moved to the space where there is higher steady pressure through the liquid flow again, the bubble unexpectedly ruptures or blows up. This type of hydraulic flow occurrence is known as valve cavitation.

The straight reason of cavitation is flare-up occurring due to unexpected change of resistance. Flare-up or flashing is pertaining to the high pressure of soaked or saturated liquid after decompression into a part of the saturated steam and saturated liquid, bubble and the initiation of smooth friction on the surface of the components.

The effective pressure can be up to 2000Mpa, which considerably surpasses the fatigue failure limit of all most all metal materials and this occurs when the bubbles burst while cavitation. The vital cause of noise is bubble rupture. The vibration generated by this can give rise to the noise, which may be up to 10KHZ. The more bubbles, the more grave is the problem of noise. Further more, the sustaining capacity of the valve goes down due to cavitation which leads to damage to the valve which may again become a reason of leakage. At this juncture, the question arise is “How to Avert Valve Cavitation ?”

The engineering & technological department at 4Matic suggests the following processdual remedyas the answer and solution to the above said problem.

-

MULTIPLE STAGE PRESSURE REDUCING :

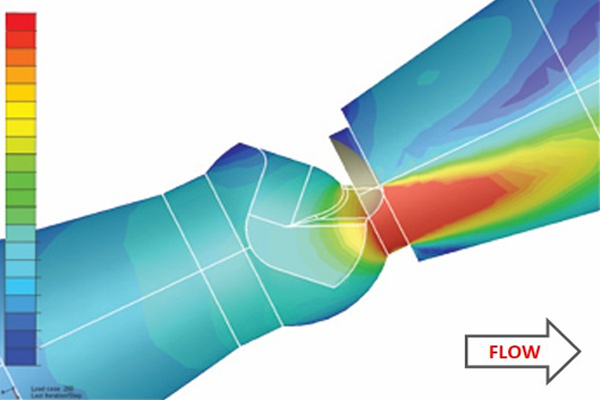

In this procedure, the pressure drop is made through the internal smaller parts of the valve, due to which the pressure in the contraction section becomes more than the steam pressure, resulting into keeping away from the generation of steam bubbles, which ultimately prevents cavitation.

-

INCREMENT IN THE HARDNESS OF THE MATERIAL

One of the major reasons of valve damage is that, the material hardness can not withstand the effective force generated by the bubble burst. To make a hardened surface, the thing to be done is surfacing or spray welding of stryker alloy based on the stainless steel. If it is damaged once, then again surfacing or spray welding for the second time yields an extension to the service life span of the equipment, which ultimately becomes the reason of decrease in the maintenance cost.

-

POROUS THROTTLING DESIGN

The flow of liquid pressure is higher than the saturated vapor pressure due to specific seat and disc structure. In the valve of the kinetic energy, the concentration of injection liquid turns into heat energy. This process diminishes the generation of air bubbles.

Furthermore, making the bubble burst in the centre of the sleeve to avert the damage that may occur straight away on the surface of the seat and disc.