At present hydrogen, generally is being observed as a main benefactor for resolving the factor of climate change and as such there is an urgent requirement for dependable and attested equipment. As for valves for the purpose of pure hydrogen and hydrogen mixture, 4Matic with a goodwill of more than three decades in the field has a track record of noted accomplishments.

Even though hydrogen is being made and is in use since so many years in the industrial sector, there are no particular norms or standards accessible which define valves for use with hydrogen. It is therefore very important to workout certain standard/s for industrial valves, functional with hydrogen.

Anyway, as the case may be, 4Matic with its progressive presence in the field of industrial valves since a period of more than 30 years has successfully evolved triple offset butterfly valves, Control and Check valves which have a proven track record for their viability for the usage in hydrogen applications.

As for any particular need/s for the valves which have to be operational for hydrogen utility, certain benchmarks with regard to material choosing have to be taken into consideration.It is commonly understood that hydrogen is likely to create degradation of material e.g., embrittlement and likely to degrade surface treatments too. As such, it is a very vital issue to choose right material. Austenitic stainless steel is generally chosen for smaller sizes of valves. However, stainless steel becomes a costly selection for large sizes i.e., more than four inches and therefore, at this point, the use of alternative materials becomes a matter of interest.Carbon steel is generally applied for the components which carry pressure, while for the internal parts the accessibility of very many alternatives is available.

TIGHTNESS

As for the gases which have likelihood to be flammable such as hydrogen, a very important aspect to be taken into consideration is Leak Tightness. One-piece castings for valve bodies is commonly used. The one-piece design averts a leak track to atmosphere when compared to two or three-piece split body designs.Moreover, the stem is fitted with a genuine effectual sealing.

As far as testing is concerned, test and acceptance norms are agreed upon with the consumer in advance.This makes it sure that the valve is viable for the desired application with total cost effectiveness and this also is a crucial point to be clarified. If there is outdoor installation of the valve, as in the case of, in a gas metering station, where there is less leakage to atmosphereas compared to when it is installed in an enclosed place.

Furthermore, it is also known that helium seems to be most feasible test medium, as it is very secure gas to operate with. Helium molecules are in fact smaller than hydrogen (H2) molecules and because of this while having a test a seal operates nicely with helium, it will also provide a fruitful barricade against hydrogen. It is but obvious that the tests can be carried out with hydrogen or hydrogen/nitrogen mixers. Nevertheless, in such cases a particular consideration to safeguarding is a must. It is also a matter of interest to be taken into account that various testing methods are applied to hunt out helium and hydrogen. Helium is generally found out by a mass spectrometer, where as hydrogen is determined through a detection inquiry.

ZERO EMMISSION VALVE

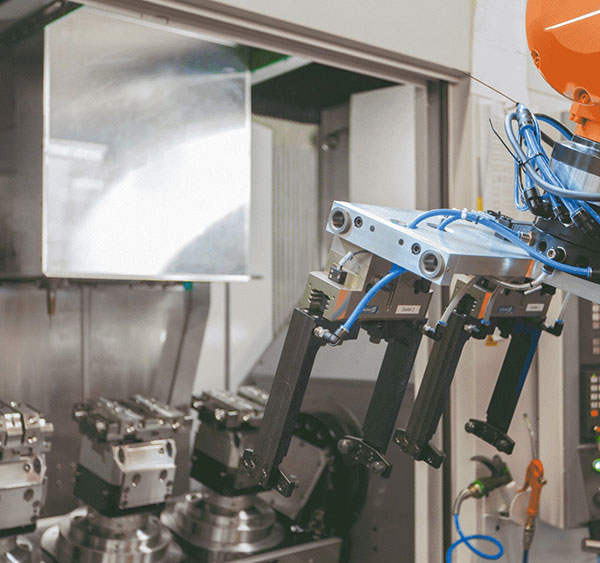

For the clientele who are searching for emission control in totality should take into account that 4Matic Valves has developed the valve that has no dynamic seals to the atmosphere. Regular valve designs depend on stem seals to stop process fluid leakage to atmosphere. These dynamic stem seals are vulnerable to wear and tear and degradation, over the passage of time reflecting an increase in emissions. Through doing away with the stem seal entirely, 4Matic’s zero emission valve stops any leakage to environment and that too for a period of total working life of the valve.In short, it is rightly stated that “An electric actuator has been integrated inside the valve body.”

Stem leakage has all the possibility to go to high level.By installing 4Matic zero emission valve, the emission from stem seal leakage can be brought down to zero.This valve is advantageous also on the ground of cost effectiveness as its power consumption is very low and also calls for a low actuation force.This subscribes in to the direction of accomplishing Scope 2 GHG goals – decreased indirect emissions. To sum up, these are two powerful justifications for a maintainable evolution of hydrogen transmission systems.