Float Valve Manufacturers in Ahmedabad

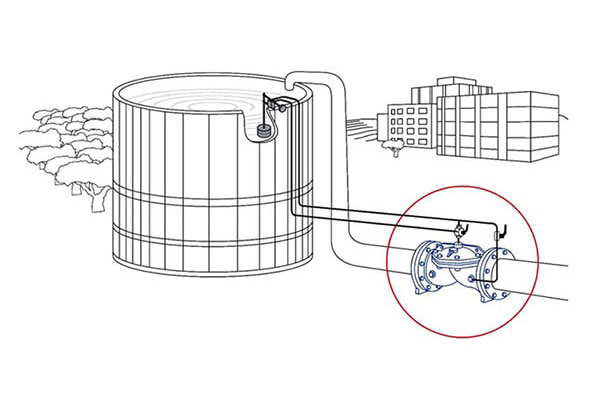

Float valves are incredibly useful devices that mechanically control the level of fluid within a storage tank. This is achieved by the buoyancy-based response of the floating ball to the changes in fluid level within the tank, and then opening or shutting the valve in response to these fluctuations.

Float valves are commonly used for a wide array of applications including for water tanks, water supply boards, water distribution, water management, fluid level control and a variety of other systems, making them a highly versatile product.

The Working of a Float Valve :

The float valve is generally used in a reserve water tank and baasically it has three parts, the Valve, the Stem and the Float Device. The valve creats a tight seal by blocking the water through the pipe as the stem rises. The valve is connected to the float device through the stem. In certain applictions the stem is also used to adjust when the water flow will be blocked. The float device is generally round and is filled with air. This device is air tight and is attached to the stem. Because of the trpped air in the float device it has buoyancy and will float atop the water. As soon as the water is released from the reserve, the float device drops, paving the way for the valve to open. The valve will remain open until the float device is raised to a pre – fixed level by the rising water. As a result the valve will be shut off.

Common Use of Float Valve :

The standard household toilet is the most common application of the Float Valve. On the back of the toilet, the float valve is fixed inside the reserve tank. Majority of the toilet models have a baloon shaped float valve fixed to a stem, which extends across the tank to the float device. When the toilet is flushed, the float drops as the water is released and the valve becomes activated. Again the valve will be closed, as the tank will refill. Now, the toilet can be flushed again.

Ball Float Valve :

Ball Float Valve is another type of Float valve. In this application the valve seals a vent line, in steade of shutting the flow of liquid. A ball float is held in place by a bracket which keeps it properly positioned below a vent line. The ball will float up and will cover the vent pipe opening as soon as the water or other liquid rises. Therefore it prevents any liquid from moving up the vent line. This application can also ristrict the entry of more liquid into the reserve tank if the seals are working properly.